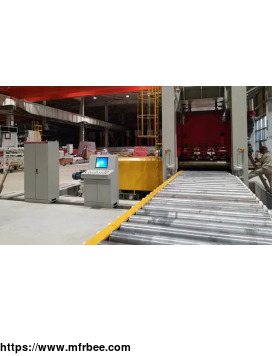

W43B Leveling Machine

Specifications

EZHONG W43B sheet leveling machine adopts a straightening roller layout design of six upper and lower seven. If you need to add straightening rollers, you need to make a reservation. The feed

roller is preset with a spring compression design plan to avoid abrasion of the feed roller, slipping, etc. The middle straightening roller is designed with four worm gear lifts for fine-tuning,

and the lifting of the two straightening rollers is synchronized, which is convenient to adjust the gap of the straightening roller. Models with the width size you need can be customized according

to customer requirements. The application scope of EZHONG sheet levelers covers many industries such as machinery, metallurgy, building materials, chemicals, electronics, electric power, light

industry, etc., especially in shipbuilding, rolling stock, boiler bridges, metal structure factories and other industries, becoming an indispensable necessity in production product.

Working Principle Of W43B Leveling Machine

Using a closed frame, the corrective force is enclosed inside, the frame is simple in appearance, the overall rigidity is good, and the foundation can be leveled with full load;

The depressing corner mechanism and the corner mechanism are combined together, using group technology, using two sets of the same power system, using YEJ type motor drive, so that the movable beam

can accurately and automatically position and quickly swing angle;

Working Principle Of W43B Leveling Machine

The upper and lower support digs are multi-row diameter supports, arranged with the working spokes in an up and down arrangement. The bottom is equipped with an integral inclined iron adjustment

mechanism. Manual fine-tuning is used to adjust the upper and lower leveling and braiding spokes to maintain the rigidity of the work roll and level the thin plate. When wavy bends, convex-concave

buckling, and buckling are deformed, support spokes are needed to change the convexity of the working spokes, and the opening amount and inclination angle of the upper leveling spokes can be

manually adjusted, which can easily adapt to the correction requirements of wavy bends and scoop-shaped plates.

Working spoke journals all adopt self-aligning needle roller bearings for rolling mills. Compared with copper sleeves, they have high transmission efficiency, long service life, the low frictional

resistance of working spokes, greatly improved non-slip conditions, and can straighten thinner steel plates.

Advantage of EZHONG W43B Sheet Leveler

Using a large number of advanced manufacturing technologies to carry out SOLIDWORKS full three-dimensional digital design, etc.

PLC+touch screen+button, all working parameters can be set in the man-machine interface, with parameter memory, storage, power-off memory functions.

Human-machine interconnection, the control system of this sheet leveler has the functions of storing, recalling and editing process and equipment parameters. When in use, the inlet and outlet

reductions can be set according to parameters such as plate thickness, plate width, material strength, etc., to realize automatic adjustment.

Automatic adjustment device for the opening of the sheet leveler. Before the plate enters the leveling machine, the plate thickness, width, and material are measured by scanning the plate

information processing unit, and the signal is transmitted to the electrical control cabinet. The opening amount calculation is automatically performed, and the opening amount of the sheet leveler

is adjusted. The value is confirmed after correction. Make adjustments again.

Now the leveling machine price is reasonable, if you have needs, please contact us.

If you want to know more sorts of metal sheet rolling machine, please visit our website.

- Country: China (Mainland)

- Business Type: 制造商

- Founded Year: 1958

- Address: NO.1, Sihai Avenue

- Contact: ezhong group