Micro Piston Pump

Specifications

Micro Piston Pump is a type of high-cost performance but high precision fluid dispensing pump for microfluidics from microliters to milliliters, some of them are equipped with a control driver

while some not to meet different customers' needs. Standard volume 6ml piston pump works at resolution 1.57μL with repeatability of 0.3%-0.7%, users can control the motor by themselves or use our

stepper driver with communication control. The micro piston pump is a very popular and smart precision syringe pump choice for medical systems.

Types of Micro Piston Pump

Precision Dispense Piston Pump

Precision dispense piston pumps was designed to replace high cost industrial china syringe pump when application requirements are relatively lower in some fluid delivery systems, it has very high

cost performance but with high function performance such as corrosive resisting fluid path, communication control unit, high precision motors etc., it is the most key part in medical analyzers.

Advantages of Micro Piston Pump

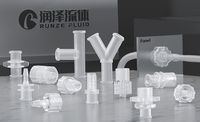

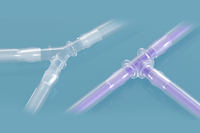

High Quality Materials Selection

RUNZE micro piston pumps are made of the ceramic cylinder and PC outlet to meet the increased requirements of analysis, it is biocompatible corrosive resisting, non-leakage and reusable in fluidic

systems, small footprint and high-cost performance makes it famous star in medical analytical instruments.

Accurate Control Units

The micro piston pumps are composed of a communication driver, high precision stepper motor, optical encoders to work together on achieving the most reliable control systems, besides they are

maintenance-free for convenient use.

High Cost Performance

Micro piston pumps have the most configurations from our MiNi SY-04 syringe pumps, the only difference if syringe part, but its cost is much lower than MiNi SY-04 syringe pumps because it is mainly

used in low-cost medical devices in large quantities, system cost must be lowered down from each key parts inside, micro piston pumps rightly do this job.

Applications of Micro Piston Pump

Micro Piston Pump is one of the high precision components in medical fluid systems, all the wetted materials are corrosion-resisting to meet the needs of most fluidic systems. Fluid control

equipment is widely used in environmental analyzers, laboratory instruments, medical equipment, petrochemical systems, food and beverage vending machine, bio-pharmaceuticals analysis, and metering.

High stability is the most important factor, quality materials, complete software, high-quality molding, and machining make these realized to a high level.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Africa

- Address: Room 201 3rd Building Runjing International, No.9 Tianxing West Road, Dongshan Street, Jiangning District, Nanjing

- Contact: runzefluid .com