Miniature Peristaltic Pump

Specifications

Miniature Peristaltic Pump head is very high cost performance model for small flow rate applications like the miniature peristaltic pump, small layout, 4 rollers structure and easy tubing

replacement make it very welcomed by medical and lab equipment, flexible block designs enable it self-adapt to different tube sizes in a wide range.

Specification of Miniature Peristaltic Pumps

Model No. RZ1030-4

Pump Roller POM 4 rollers

Pump Head ABS engineering plastic

Fast Tubing YES

Pump Color Black

Compatible Motor Stepper motor/DC motor

Motor Speed 0-500rpm

Flow Range 0-170ml/min

Tubing Size ID0.64-3.0mm WT0.8-1.0mm OD≤5mm

Tubing Life Silicone≥200H BPT Rubber≥1000H

Pressure Rating Up to 2 bar(30psi)

Working Environment 0-40℃, <80% non-condensing

Max DB 65db

Suction 5 meters

Head 8 meters

Dimension (L*W*H) 57*65*23mm

Net Weight 58g

1. Tubing life measured by pumping pure water under continuous working at the room temperature 20℃ and no extra pressure until it cracks

2. Tubing life vary from different medium, motor speed, working environment, the lower motor speed and mild fluids help to extend the service life of tubing

3. Please replace new pump tube regularly to achieve higher precision constant liquid transfer

Dimension (unit: mm)

How Do Micro Peristaltic Pumps Work?

The mini peristaltic pumps are low-pressure product pumps, the general working pressure does not exceed 0.7Mpa, and the large peristaltic pump (hose pump) can reach more than 1Mpa. The miniature

peristaltic pump alternately squeezes and releases the elastic delivery hose of the pump, so that the peristaltic pump draws fluid. Just like pinching and squeezing a hose with two fingers, the

hose moves with the fingers, and the liquid creates a negative pressure in the hose. There are many types of fluids transmitted by micro peristaltic pumps, not only fluids with particles, but also

fluids with strong acids, strong bases and strong organic solvents. You only need to choose a hose suitable for the fluid.

What Are the Advantages of Using Micro Peristaltic Pumps?

1. No pollution: the fluid only touches the miniature peristaltic pump tube, not the body of micro peristaltic pump ;

2. High precision: high repeatability precision, high stability precision;

3. Low shear force: micro peristaltic pumps are ideal tools for conveying shear sensitive and corrosive fluids;

4. Well-sealed: the micro peristaltic pump has a good self-priming ability which can be idling, and can prevent backflow;

5. Simple maintenance: no valves and seals.

6. Affordable mini peristaltic pump price: miniature peristaltic pump head discs are usually made of plastic to reduce costs.

How to Maintain a Micro Peristaltic Pump?

The composition of the mini peristaltic pumps is divided into three components: the driver, the pump head, and the hose. During use, the hose is consumable and needs to be replaced regularly. The

driver and pump head are maintenance-free parts, and only need to be dry and cleaned daily. Work without special maintenance.

In the use of the miniature peristaltic pump head, the common damages include the following situations, which need to be paid attention to during use: First, the speed is too high, exceeding the

design speed requirements of the pump head; Second, accidental fall from high altitude, resulting in deformation or damage of the pump head; Third, the leakage of the hose causes the liquid to

enter the rollers of the pump head and the main shaft bearing, and damage the bearings.

Now the micro peristaltic pump price is reasonable, if you have needs, please contact us.

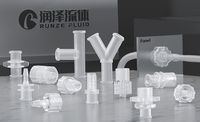

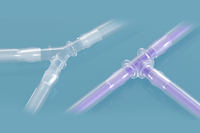

RUNZE FLUID, a professional microfluidic components supplier, offers a complete product range of microfluidic instrumental components including industrial syringe pumps, multiposition valves,

plastic fittings, peristaltic pumps, fluidic tubing, gastight syringes, OEM molding parts, which play an important role in fluid analytical instrument prototyping and production, like water, blood,

chemicals, diathermic oil, etc.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Africa

- Address: Room 201 3rd Building Runjing International, No.9 Tianxing West Road, Dongshan Street, Jiangning District, Nanjing

- Contact: runzefluid .com