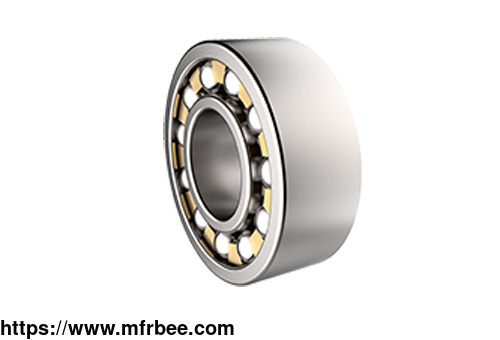

Self-aligning ball bearings have two rows of balls and two continuous tracks of deep groove ball type in the inner ring. The outer ring has a spherical track with the center of curvature coinciding

with the center of curvature of the bearing. This gives the inner ring, the balls, and the shaft of the cage a deflection area. Self aligning linear ball bearings are mainly used to carry radial

loads and light axial loads, but cannot carry pure axial loads. THB-Bearings is a professional self aligning ball bearing manufacturer offering you two types of self aligning linear ball bearings

as follows. The followings are self-aligning bearing types. Click and check more information about self aligning linear ball bearings.

Self Aligning Ball Bearing Types

Self-aligning Ball Bearing

Self-aligning ball bearings are particularly suitable for misalignment applications where mounting accuracy is difficult to guarantee or where shaft deflection may cause misalignment. Open and

closed (with seals or dust caps) designs are available. The inner ring with tapered bore is also available on request for use with tightening sleeves.

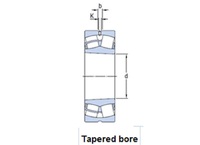

Self-aligning Ball Bearing With E-tended Inner Ring

The difference from the standard aligning ball bearings is that the inner ring is extended with a positioning groove at one end of the ring, which is positioned by a pin when it is installed on the

shaft to avoid the inner ring from turning on the shaft.

Self-aligning Ball Bearing vs Basic Ball Bearing

Self-aligning ball bearings are usually composed of an outer ring with a spherical raceway, a double raceway inner ring, two rows of steel balls and a cage. The inner ring with two rows of steel

balls and the cage can swing at a certain angle along the outer ring spherical raceway. Compared with ordinary ball bearings, this allows self-aligning linear ball bearings to work normally even

when the shaft is slightly misaligned with respect to the bearing housing. Therefore, the self aligning linear ball bearings are especially suitable for the application of misalignment caused by a

component structure that is difficult to ensure installation accuracy or shaft deflection, and solves the problem that ordinary ball bearings need to be accurately aligned, and can be used in many

scenes that are difficult to accurately align. However, under the premise of not achieving precise alignment, although self-aligning ball bearings can operate normally, they cannot adapt to

excessively fast working speeds. Therefore, compared with ordinary ball bearings, self-aligning ball bearings are usually used in occasions where the speed is not high, the requirements for noise

and vibration are not high, and the installing and the un-installing are difficult.

Choice and Installation of Self-aligning Ball Bearing

We usually choose the bearing products according to the specific application, like the load, speed and space constraints, etc. But when choosing a self-aligning ball bearing, we not only need to

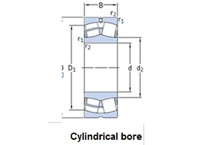

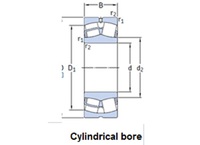

choose it according to the load, speed and space constraints of the application scenario, but also need to consider the amount of misalignment and shaft deflection. The basic design of a

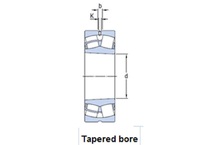

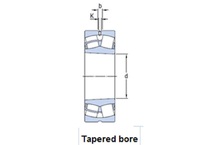

self-aligning ball bearing has a cylindrical hole, or in some size ranges, a tapered hole. We usually will choose to heat the bearing before installing it. However, if the bearing needs to be

cold-mounted in special circumstances, the installation tool must be a special sleeve tool to ensure that the installation force will not be transmitted through the steel ball during the

installation process, so that the steel balls and raceways will not be damaged during the installation process. If the bearing has a tapered hole, it can also be installed using a two-step

hydraulic drive method.

Self-aligning Ball Bearing Application

Self-aligning ball bearings are commonly used in applications where misalignment may occur, such as:

Conveyor systems: Conveyor systems often experience misalignment due to belt tension, belt stretch, or bearing wear. Self-aligning ball bearings can help to compensate for this misalignment and

ensure smooth operation.

Paper manufacturing equipment: Paper manufacturing equipment, such as pulp and paper mills, can experience misalignment due to the high-speed rotation of machinery. Self-aligning ball bearings can

help to minimize the effects of misalignment and ensure reliable operation.

Industrial pumps: Industrial pumps can experience misalignment due to thermal expansion, vibration, or bearing wear. Self-aligning ball bearings can help to compensate for this misalignment and

ensure efficient operation.

Agricultural machinery: Agricultural machinery, such as tractors and combines, can experience misalignment due to uneven terrain or shock loads. Self-aligning ball bearings can help to absorb these

shocks and ensure reliable operation.

Mining machinery: Mining machinery, such as crushers and screens, can experience misalignment due to heavy loads and high vibration. Self-aligning ball bearings can help to minimize the effects of

misalignment and ensure reliable operation.

Overall, self-aligning ball bearings are a versatile type of bearing that can be used in a variety of applications where misalignment may occur. They can help to improve the reliability and

efficiency of machinery by compensating for misalignment and reducing the risk of premature failure.

THB Bearings, as a professional self aligning ball bearing manufacturer in China, knows clearly about self aligning ball bearing applications and specializes in providing solutions for

Self-aligning Ball Bearing applications across different industries. If you are looking for a reliable self aligning ball bearing manufacturer, please feel free to contact us!

Textile Mining Industries Agriculture Heavy Machinery

Power Machinery Medical Devices /

Now the price of china v roller bearing is reasonable, if you have needs, please contact us.