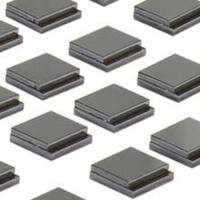

WLP Infrared Detector

Specifications

Wafer-level packaging is an increasingly mature form of packaging recently. The WLP infrared detector uses an InfiRay self-developed 12 μm high resolution (640×512, 384×288 or 256×192) VOx thermal

imaging sensor. Technically speaking, it can achieve smaller size, higher efficiency, higher output and lower cost. It can be used in industrial and civil products, and can also be widely used in

the field of consumer goods, making it possible for infrared thermal imaging technology to enter the daily lives of ordinary people.

WLP INFRARED DETECTOR FEATURES

VOx Microbolometer Technology

VOx Microbolometer Technology is applied in WLP Infrared Detector.

Low Power Consumption

WLP ir detector sensor is smaller and more efficient, making it more suitable for low power consumption micro-module applications.

Light-weighted Package

WLP Infrared Detector does not use heavy metal and ceramic materials, and the infrared detector chip is aligned with the silicon window one by one, which is much lighter.

High Sensitivity

With features of high sensitivity and reliability, WLP ir light sensor is able to meet HD thermal imaging requirements.

Smaller Thermal Time Constant

It's much faster to capture moving targets and form Ultra Clear thermal images.

- Country: Afghanistan

- Contact: in firay