BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Product Quick Detail

- FOB Price

- USD $8.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Nanjing City,Jiangsu Province,China

- Packaging

- Custom wooden box

- Delivery

- 15-90 working days

Specifications

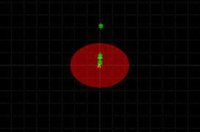

Eddy current weld testing is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the

welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

Eddy current testing of welds is a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the

surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount

of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current weld inspection is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. This eddy current

machine is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01\02 NDT weld testing equipment is used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks.

The eddy current testing of welds can effectively detects slow and long-term injuries caused by welder failure during the production process.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector performance

Detection channel Double channel

Detection speed 1~500m/min(online)

Frequency range 100Hz-1MHz

Gain 0~99dB, step 0.1dB

Phase rotation 0-360 °step1 °

High pass 0.1Hz~650Hz

Low pass 1Hz~10000Hz

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

High precision end and end-to-tail signal removal

High precision real-time, delayed alarm output

Fast digital/analog electronic balance

Memory track delay blanking function

Non-equal amplitude phase/amplitude alarm domain

Remote automatic help system

Synchronous alarm output for internal and external clock control

As one of ndt equipment manufacturers, we can offer sorts of ndt testing machine for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Contact: bkneddy .com