IPL Filter

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Chang Chun,P.R. China

- Packaging

- Carton

- Delivery

- 30 days

Specifications

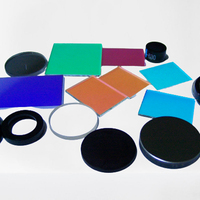

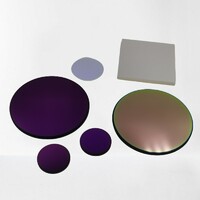

IPL filter blocks the UV wave and transmits the useful wave from 400nm to 1200nm for laser equipment with Xenon Lamps, such as photorejuvenation hair removal, vascular and acne treatment, skin rejuvenation.

IPL Filters Regular Maintenance and Cleaning Importance

Regular maintenance and cleaning of ipl filter 640nm is of utmost importance for several reasons. Firstly, it helps to ensure the longevity and optimal performance of the filter. As IPL filter are used in various applications, they tend to accumulate dirt, dust, and other particles over time. If not cleaned regularly, this build-up can obstruct the flow of air or light through the filter, leading to reduced efficiency and effectiveness.

Secondly, regular maintenance and cleaning also contribute to the overall safety of the filter and the equipment it is integrated into. Accumulated debris may pose a fire hazard or increase the risk of electrical malfunctions, potentially causing damage to the equipment or even injury to users.

Moreover, clean IPL filters also prevent contamination and improve the quality of the filtered output. In applications such as medical or skincare treatments, where IPL filters are used to eliminate impurities or harmful wavelengths, regular cleaning ensures consistent and reliable results.

Proper maintenance and cleaning procedures for IPL filters may involve methods such as gentle brushing, air blowing, or using specialized cleaning solutions. Optical filter manufacturers and optical manufacturing companies like TC Optics, usually provide guidelines or recommendations for the adequate cleaning frequency and techniques.

In conclusion, IPL filter regular maintenance and cleaning are crucial for maintaining their performance, ensuring safety, and guaranteeing optimal outcomes in various applications.

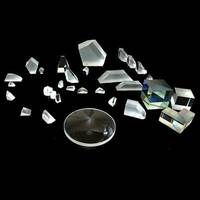

Tcoptics, as an excellent optical component manufacturer, offers a wide range of optical component for you to choose from.

- Country: China (Mainland)

- Address: No. 1567 Liu Ying Lu, Kuan Cheng District, Chang Chun,P.R. China

- Contact: Aamina Gao