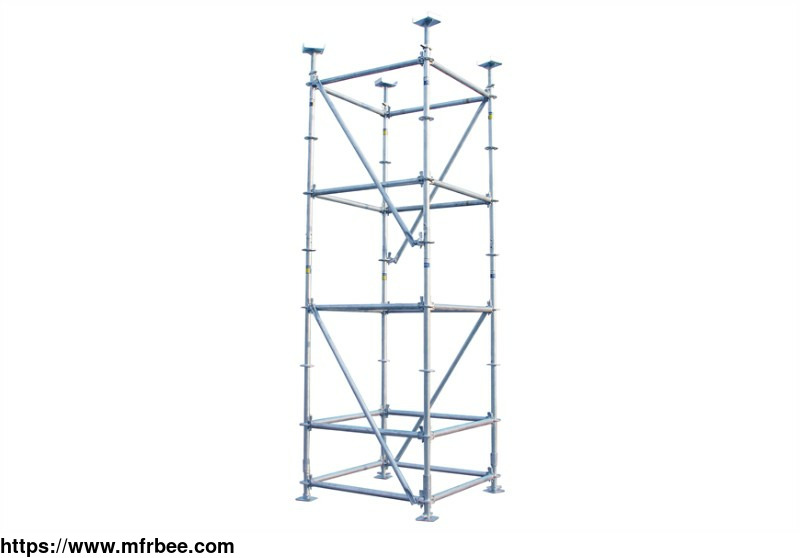

Ringlock Scaffolding

Specifications

TECON Scaffold Ringlock is designed and manufactured as the most convenient and efficient ringlock scaffolding system. It only consists of a few user-friendly components such as standard, ledger,

diagonal brace, screw jack etc.. It can be used as a shoring system, facade platform, and work access for both the construction site and the industrial field

Features of ringlock scaffolding for sale

Quick erection and dismantling with only a hammer

Safety and stability due to rigid wedge connections without loosening

Durability and less maintenance due to high strength steel and hot-dip galvanizing finishing

It can be used as an access tower with stairs inside to the site at the height

It can be used as shoring support to meet heavy load requirements

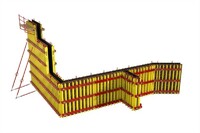

It can be used as a façade platform for site crew protection and a working platform at the height

Ring lock scaffolding dimensions Standard

Eight holes on each rosette allow various tight connections from the ledger to the diagonal brace

Minimum 60µm hot-dipped galvanization

Main sizes of standard: 0.5 /1.0 / 1.5 / 2.0 / 2.5 /3.0 m

Main sizes of ledger: 0.3/0.6/0.9/1.2/1.5/1.8/2.1/2.4 m

High strength steel material: Q355 as standard

Despite of 48.3mm diameter standard, 60mm diameter standard is also available for heavier loading requirement

Application of Ringlock Scaffolding

Construction sites from residential & commercial buildings to fly-over roads, metro stations, ship yards, petrochemical plants and others.

Ring Lock/Ring lock scaffolding parts

Ring lock scaffolding is a type of modular scaffolding system that consists of various parts and components.

Here are the components of a ring lock system:

Standards provide the main support for the scaffolding structure.

It is typically made of steel tubes and has connection points at regular intervals.

Ledgers connect the standards, providing lateral support.

It is also made of steel tubes and has connection points on both ends.

Diagonal Braces provide stability and rigidity to the scaffolding structure.

It connects the standard and ledger at an angle.

Rosettes are attached to the standards, ledgers, and braces to create a secure connection.

It typically has multiple connection points, allowing for various configurations and angles.

Base Jacks are adjustable and placed at the bottom of the scaffolding structure to provide stability and level the scaffolding on uneven surfaces.

The height can be adjusted by extending or retracting

Transoms are placed between ledgers to provide additional support and create a working platform.

They are typically used in conjunction with scaffold planks.

Scaffold Planks are placed on the transoms to create a safe working area.

Scaffold planks are usually made of wood or metal and come in various lengths.

Toe Boards are attached to the ledgers and transoms at the edge of the working platform to prevent tools or materials from falling.

Couplers are used to connect scaffolding components.

It ensures a secure and rigid connection between standards, ledgers, and other parts of the scaffolding system.

Ladders allow workers to climb up and down the scaffolding structure safely.

It can be attached to the standards at various intervals.

For more information about formwork and scaffolding, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2013.11.13

- Address: Room1105-1110, Block A, Building 2, LEFO Commercial Center, Wuzhong District, Suzhou, Jiangsu Province, China

- Contact: Edgar Chow