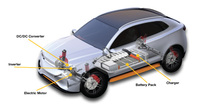

ELECTRIC VEHICLE BATTERY CASE

Specifications

electric car battery case, also known as electric car battery box, is one of the most important components in new energy vehicles. The best NEVs make use of aluminum alloy for the battery case structures as key components that offer security for their battery payloads, but also structural rigidity for the vehicles. Our battery box case has high-temperature resistance, corrosion resistance, high electrical conductivity, and good heat transfer performance. Large scale battery case castings are an exciting area for die cast aluminum casting technology.

Electric vehicle battery box overview

The main purpose of the battery shell of an battery housing electric vehicle is to accommodate and protect the battery. They come in different shapes and sizes, and aluminum and steel are the traditional materials for battery housings. The main obstacle to the large-scale adoption of electric vehicles is the fear that they will not be able to drive far enough on a single charge. Composite materials can provide an improved alternative to significantly improve the performance of electric vehicles. In order to alleviate this problem, it is necessary to provide qualified cars, and the parts that make up them must also have these qualities.

ADVANTAGES

Lose weight. The main driving force for choosing composite materials is that if the shell is made of 100% composite materials instead of aluminum, weight savings of up to 40% can be achieved, which will play an important role in the large-scale adoption of electric vehicles.

Reduce noise. Noise is the result of acoustic propagation of vibration or noise in the cabin.

Although not obvious in other ways, it is important in terms of commerciality and driving experience.

Security issues. The strength and stiffness of the composite battery shell exceeds that of aluminum or steel and can be designed as part of the body structure to protect not only the battery but also the passengers.

Pultrusion. Mass production is essential to reduce overall costs.

Continuous manufacturing methods can be used to produce electric car battery tray components for electric vehicles, and Pultrusion process can be used to produce stronger but lighter products.

EMP Tech, as an excellent die casting manufacturer, offers a wide range of custom aluminum die casting for you to choose from.

- Country: Afghanistan

- Address: NO.38 Duanzhou San Road,Zhaoqing(526060),Guangdong,China

- Contact: Lia Gan