Abrasives

Specifications

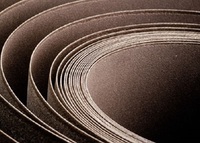

We are specialists in the coated abrasives industry. We supply RMC brand abrasive paper, abrasive cloth, velcro disc, flap disc, flap wheel, non-woven abrasives, surface condition abrasives, sponge

abrasives, net abrasives, film abrasives, polishing pad, grinding cube abrasives, abrasive belt, fiber disc, stripe abrasives and so on.

About the abrasive manufacturing process

Manufactured Abrasives from our wholesale abrasive material suppliers are made by heating or chemically treating metals or minerals to give them physical properties needed to abrade, clean, etch,

grind, polish, scour, or otherwise remove material by rubbing action (as in a grinding wheel) or impact (pressure blasting). Their most important properties are hardness, toughness (rigidity),

grain shape and size, the character of fracture, and purity (uniformity). Additional considerations include thermal stability, bonding characteristics, cost, and availability. No single property is

paramount for any use.

Why Are Abrasives Important?

Abrasives are primarily used in metalworking because their grains can penetrate even the hardest metals and alloys. However, their great hardness also makes them suitable for working with such

other hard materials as stones, glass, and certain types of plastics. Abrasives are also used with relatively soft materials, including wood and rubber because their use permits high stock removal,

long-lasting cutting ability, good form control, and fine finishing.

As one of the most professional abrasive manufacturers, we provide abrasives video, abrasive wear resistant materials, abrasive raw materials, abrasive tools, etc. For more information about

abrasive material types and properties of abrasives pdf, please feel free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,Middle East,Oceania

- Founded Year: 2002

- Address: No.8, North Road, New & High Industrial Zone, Zibo, Shandong,

- Contact: Guizhen Zhu