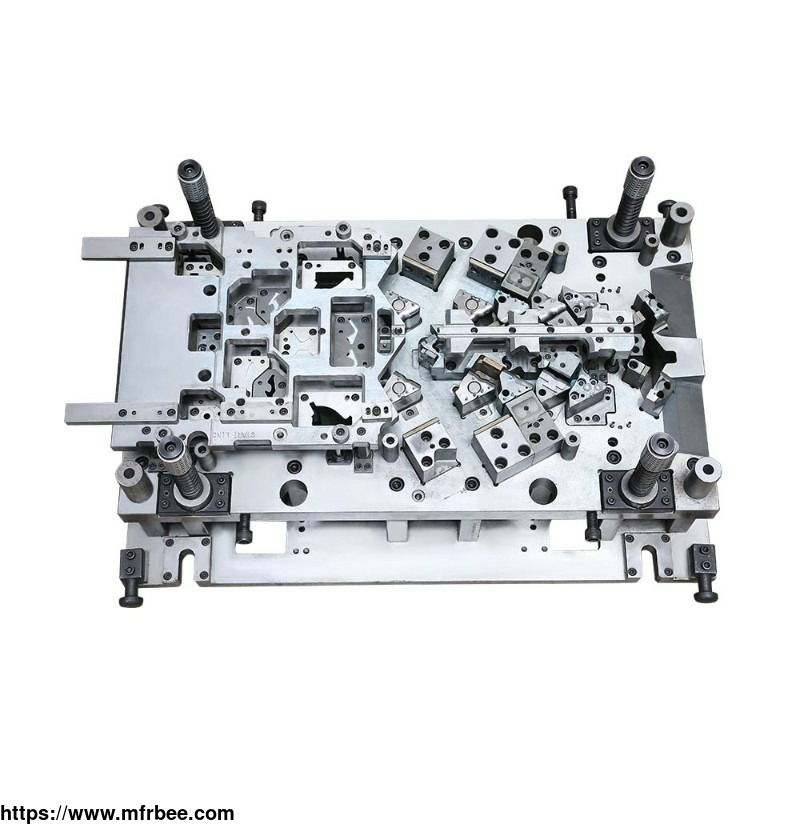

Automobile Body Cross Beams Mould

Specifications

The steps for manufacturingmolds for automotive

1. Design: Use computer-aided design (CAD) software to create a prototype or 3D model of the part, and then design a mold that exactly matches the part. During the design process, factors such as the shape, size, and material of the part need to be considered.

2. Make the mold model: Make the mold model, you can use CNC machine tools, 3D printing or handmade.

3. Make the pattern of the mold: convert the pattern of the mold into the pattern of the mold, which can be made by casting, forging or CNC processing.

4. Mold processing: According to the mold of the mold, a complete mold can be manufactured, which can be processed by CNC machine tools, electric sparks, wire cutting and other technologies.

5. Assembly and debugging: Assemble and debug the manufactured mold to ensure that it can work normally.

6. Mold trial: Conduct mold trial to check whether the shape, size, surface quality and other parameters of the workpiece meet the requirements.

7. Mold maintenance: Carry out regular maintenance and maintenance on the mold to prolong its service life and ensure its stable performance.

- Country: China (Mainland)

- Founded Year: 2008

- Contact: Wei luode