Car Seat Mould for Kids

Specifications

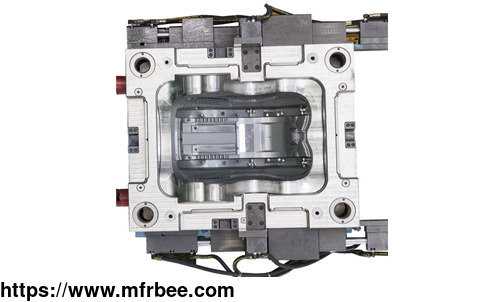

Car Seat Mould for Kids

Child mouldy car seats specially designed to protect children from injury or death in a collision. The main structure of the child safety seat is a plastic part produced by the child safety seat

mold, and there are also some metal parts to fix or support these plastic parts. The product design and mold design of the child safety car seat mold are the most important. For example, the

thickness and design of the ribs of the plastic parts will lead to the surface of the plastic parts with sink marks, and the requirements for steel selection and mold processing equipment are also

very high. Green Vitality provides professional solutions to customers for each project.

High-quality Injection Mold for Child Safety Seat

The production output of mold on car seat is very large, so high-quality child safety chair mold is very important. An efficient mold cooling system can shorten the injection cycle and save more

processing costs and time. We are very concerned about the mold cooling system and mold production stability. Our goal is to ensure customers to run as little mold repair work as possible, and be

able to perform mass production efficiently and stably.

Basic Information for Child Safety Seat Mold

Specifications of Green Vitality Plastic Injection Mold

Description Child safety seat mold

Plastic material PP

Mould dimension(mm) 1600*1000*980

Mould weight (T) 10T

Mould cavity&core steel P20

Nos of Cavity 1*1

Manufacture time (day) 60 days

Mould life ≥500000

Molding cycle (S) 100 S

Cooling line connector type DME NS350 SERIES quick coupling,

Mold Characteristics excellent cooling system design

Short cycle time

Advantage of Green Vitality Injection Mould

We have more than 20 years of experience in plastic injection mold manufacturing, rich experience in Child Safety Seat mold.

We have advanced process and inspection equipment and regular investment in leading-edge equipment.

We can participate in and assist customers from the initial product design and development to the entire stage of mold making and product production and delivery.

We provide a perfect project Management System.

We provide innovative solutions based on varied industry experience.

We guarantee our molds for the life of your project.

As a reliable injection molding supplier, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Address: 101#, Building C, North Yongfa Hi-Tech Industrial Park, Shajing Road, Shajing Town, Bao'an District, Shenzhen, China

- Contact: Susan Qin