AUTOMOBILE BRAKE DISC MILLING MACHINE

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 1 month

Specifications

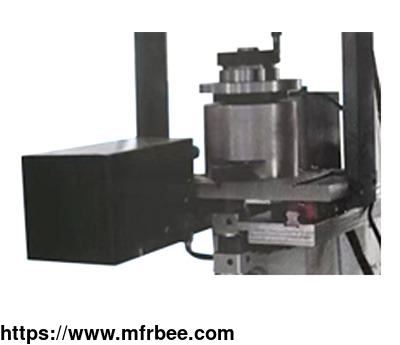

AUTOMOBILE BRAKE DISC MILLING MACHINE

The equipment is a CNC milling machine developed and produced for the milling processing of the forklift brake base plate boss. The equipment can realize automatic rotation, avoid the milling

cutter, and quickly stop and start the spindle. And can save 10 groups of programs to call at will. It adopts color touch screen parameter control design, and the workpiece pressing method adopts

hydraulic cylinder and manual valve control, which has the advantages of simple and labor-saving loading and unloading of workpieces.

THE PARAMETER OF AUTOMOBILE BRAKE DISC MILLING MACHINE

Rated total power Input voltage Enter the frequency Clamping method Product diameter Milling cutter diameter Hydraulic power Milling power Milling speed Dimensions

6KW 3*380V 50HZ Hydraulic <�φ380mm Φ18mm 2.2KW 2KW 3000rpm 2000*1700*1900mm

The Advantages Of Automobile Brake Disc Milling Machine

The equipment can realize the characteristics of automatic rotation, avoidance of milling cutters, and quick stop and start of the spindle. At the same time, the equipment can save 10 groups of

programs for users to call at will. It adopts Delta PLC, color touch screen and servo motor control. Parameters can be set by trial correction, making it easy for operators to learn and operate.

The Application Of Automobile Brake Disc Milling Machine

The equipment is mainly used for milling the boss of the brake base plate of forklift truck. The workpiece pressing mode adopts hydraulic oil cylinder and manual valve control, so that the

equipment has the advantages of simple and labor-saving workpiece loading and unloading. At the same time, all fasteners of the equipment meet the national standard level 12.9, and the rack is made

of high-strength steel plate, which effectively keeps the equipment running normally for a long time.

Other Notes Of Automobile Brake Disc Milling Machine

Automobile brake disc milling machine Main Characteristics

1

Realize automatic rotation, avoid milling cutter, and quickly stop and start the spindle.

2

10 groups of programs can be saved and called at will.

3

Adopt brand electrical components and touch screen to set parameters.

4

Hydraulic cylinder pressing method, easy to load and unload workpiece.

5

The operator is easy to learn, easy to operate, labor-saving and so on.

6

Fasteners meet the national standard 12.9.

If you want to know more kinds of vertical milling machine cutting tools, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2019

- Address: No. 28 Jinteng Road, Wuxiang, Yinzhou District, Ningbo

- Contact: ningboxihe com