Cycloaliphatic Epoxy Resin

Product Quick Detail

- FOB Price

- USD $15.00 / Piece

- Minimum Order

- 200

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 1 weeks

Specifications

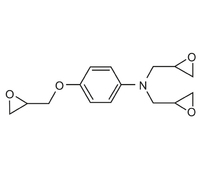

Cycloaliphatic epoxy resins refer to a series of products obtained by oxidation with butadiene and acrolein as base materials and the mixture of hydrogen peroxide and peracetic acid as oxidant.

They have a variety of applications, including 3D printing, coating, ink, adhesives, composites, and electronics, among others.

Cycloaliphatic epoxy resins may be cured by anhydride-based methods as well as UV/EB- and thermally-curable methods.

Advantages of Cycloaliphatic Epoxy Resin

The cycloaliphatic epoxide resin has strong dilution ability. There will be an obvious dilution effect when the addition amount in the formula exceeds 20%.

The glass transition temperature (Tg) of cycloaliphatic epoxy resin TTA21P(3 4 Epoxycyclohexylmethyl- 3',4'-Epoxycyclohexane Carboxylate Cas 2386-87-0) is 204 ℃, much high than the other common

epoxy resin.

The cycloaliphatic epoxy resin TTA21 has excellent adhesion on a variety of substrate surfaces.

The figure shows that the volume shrinkage of cycloaliphatic epoxy resin after UV curing is significantly lower than that of acrylate.

When 20% of the cycloaliphatic epoxy resin is added to the formula, the product has played a very positive role in overcoming oxygen polymerization inhibition.

What Is Cycloaliphatic Epoxy Resin?

Cycloaliphatic epoxy resin refers to a series of specialty epoxy resins obtained by oxidation with butadiene and acrolein as base materials and the mixture of hydrogen peroxide and peracetic acid

as oxidant. Epichlorohydrin is not selected as the synthetic base Tetra material, thus, the molecular structure does not contain any benzene ring and hydroxyl group, and the epoxy group is directly

connected to the cycloaliphatic ring through oxidation reduction.

There are many cycloaliphatic epoxy resin manufacturers, but we are one of the best choices for you.

For more information about cycloaliphatic epoxy resins and specialtyresins, please feel free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Address: Room 103-2, Building 9, NO.650 Shunqing Road, Jiuting Town, Songjiang District, Shanghai, China

- Contact: Tetra com

![TTA3150:Poly[(2-oxiranyl)-1,2-cyclohexanediol]-2-ethyl-2-(hydroxymethyl)-1,3-propanediol Ether Cas 244772-00-7](http://img2.mfrbee.com/uimg/3/70/59315_272117_0_t_TTA3150%3APoly%5B%282-oxiranyl%29-1%2C2-cyclohexanediol%5D-2-ethyl-2-%28hydroxymethyl%29-1%2C3-propanediol_Ether_Cas_244772-00-7.jpg)