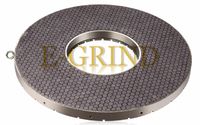

Vitrified Bond Grinding Wheels

Specifications

Vitrified bond grinding wheels are abrasive tools used for precision grinding across a range of industries. They are composed of abrasive grains, such as alumina or silicon carbide, held together

by a vitrified (ceramic) bond. The vitrified bond provides durability, strength, and resistance to heat.

E-grind Vitrified bond grinding wheels are made in both Diamond and CBN, allowing for customization based on the specific needs of the application. The diamond and CBN are held in place by ceramic

components that are fused to form the abrasive part of vitrified bond grinding wheels. The Vitrified diamond and CBN grinding wheels offer high grinding efficiency and excellent wheel shape

retention. The inherent durability and thermal stability of vitrified grinding wheels make them essential tools for grinding applications that demand precision and consistency.

How are vitrified grinding wheels made?

E grind Vitrified bond grinding wheels are made from abrasives(conventional abrasives, diamond powder, CBN powder), pore-forming agents, ceramic powder, and body(aluminum, steel, ceramic, etc).

Abrasives, pore-forming agents, and ceramic powder will be pressed and sintered into an abrasive ring first, then stuck on a body.

FAQs of Vitrified Bond Grinding Wheels

What is vitrified bond in grinding?

The vitrified bond is the type of bonding agent in grinding wheel, generally, ceramic powder or glass powder. Vitrified bond has better chemical stability, higher bonding strength, and excellent

sharpness.

What are the advantages of vitrified bonding?

Vitrified bonding offers several advantages, including high thermal stability, excellent hardness, and the ability to customize compositions. The vitrified bond grinding wheels contribute to

prolonged wheel life, precise grinding, and efficient coolant delivery.

Which industries can use Vitrified Bond grinding wheels?

Vitrified Bond grinding wheels find applications in a variety of industries, including metalworking, woodworking, ceramics, glass, aerospace, automotive, and more. They are versatile tools suitable

for precision grinding tasks across different materials.

What is the difference between resin bonded and vitrified bonds?

The main differences lie in the bonding agents. Vitrified bonds use a ceramic (vitrified) matrix, offering high hardness and thermal stability, while resin-bonded wheels use a resin matrix,

providing flexibility but with lower heat resistance. Vitrified bonds are more suitable for precision and high-temperature applications.

How do you maintain Vitrified Diamond & CBN grinding wheels?

Maintenance involves proper dressing and truing of the wheels to maintain their profile and sharpness. Additionally, using coolants as recommended for specific applications helps manage heat.

Inspecting the wheels for damage and addressing any issues promptly is crucial for optimal performance.

What is the average cost of Vitrified Diamond & CBN grinding wheels?

The cost of Vitrified Diamond & CBN grinding wheels can vary based on factors such as size, specifications. You're welcomed to contact E-grind at @e-grindabrasives.com. for accurate pricing.

Receive prompt, precise, and competitive pricing by reaching out to us today.

There are many cbn grinding wheel suppliers, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: Room 1841, Tower A, Wanda Plaza, 171#, Zhongyuan Road, Zhengzhou City, Henan Province, China

- Contact: egrindwheel com