Oil Country Tubular Goods(OCTG)

Specifications

Oil country tubular goods (OCTG) is a family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application:

Drill pipe is heavy seamless tube that rotates the drill bit and circulates drilling fluid. Pipe segments 30 ft (9m) long are coupled with tool joints. Drill pipe is simultaneously subjected to

high torque by drilling, axial tension by its dead weight, and internal pressure by purging of drilling fluid. Additionally, alternating bending loads due to non-vertical or deflected drilling may

be superimposed on these basic loading patterns.

Casing pipe lines the borehole. It is subject to axial tension by its dead weight, internal pressure by fluid purging, and external pressure by surrounding rock formations. Casing is particularly

exposed to axial tension and internal pressure by the pumped oil or gas emulsion.

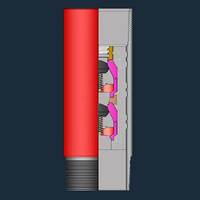

Tubing is pipe through which the oil or gas is transported from the wellbore. Tubing segments are generally around 30 ft [9 m] long with a threaded connection on each end.

Corrosion resistance under sour service conditions is a very important OCTG characteristic, especially for casing and tubing.

OCTG for Sale

Oil Field Tubing Pipe

Oil Casing

Drill Pipe

Drilling Collar

Typical Manufacturing Processes of China OCTG

Continuous mandrel-rolling process and the push bench process for sizes between 21 and 178 mm OD.

Plug mill rolling for sizes between 140 and 406 mm OD.

Cross-roll piercing and pilger rolling for sizes between 250 and 660 mm OD.

These processes typically do not allow the thermomechanical processing customary for the strip and plate products used for welded pipe. Therefore, high-strength seamless pipe must be produced by

increasing the alloying content in combination with a suitable heat treatment such as quench & tempering.

Meeting the fundamental requirement of a fully martensitic microstructure even at large pipe wall thickness requires good hardenability. Cr and Mn are the main alloying elements used to produce

good hardenability in conventional heat-treatable steel. However, the requirement for good sulphide stress cracking (SSC) resistance limits their use. Mn tends to segregate during continuous

casting and can form large MnS inclusions that reduce hydrogen induced cracking (HIC) resistance. Higher levels of Cr can lead to formation of Cr7C3 precipitates with coarse plate-shaped

morphology, which act as hydrogen collectors and crack initiators. Alloying with Molybdenum can overcome the limitations of Mn and Cr alloying. Mo is a much stronger hardener than Mn and Cr, so it

can easily recover the effect of a reduced amount of these elements.

Traditionally, OCTG grades were carbon-manganese steels (up to the 55-ksi strength level) or Mo-containing grades up to 0.4% Mo. In recent years, deep well drilling and reservoirs containing

contaminants that cause corrosive attack have created a strong demand for higher strength materials resistant to hydrogen embrittlement and SCC. Highly tempered martensite is the structure most

resistant to SSC at higher strength levels, and 0.75% is the Mo concentration that produces the optimum combination of yield strength and to SSC resistance(1).

Have a Look on the Oil Country Tubular Goods Market

Due to the increasing emphasis on the development of deepwater and offshore reserves, high-quality OCTG oil products may witness a higher compound annual growth rate across the globe. In the more

severe and challenging upstream operations, the requirements for high-quality OCTG products are even higher.

The liberalization of oil and gas by major countries in the world to increase foreign investment, which is boosting the development of the oil and gas industry, may bring an opportunity to the OCTG

market.

North America is the main regional market for OCTG drilling products. The extensive development of onshore and offshore oil and gas fields in the region may provide huge business opportunities for

companies operating OCTG business during the forecast period.

As one of oil well equipment manufacturers, we will do our best to meet all the needs of customers.

SAIGAO GROUP has solid technical strength, advanced technology, sophisticated equipment and perfect testing means. It owns over 300 processing and auxiliary equipment such as NC lathes, NC boring

machine, NC milling machine, NC grinding machine and 4 machining centers.

- Country: China (Mainland)

- Founded Year: 2008

- Address: Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

- Contact: Rex Liu