NJP-3200C Fully Automatic Hard Capsule Filling Machine

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

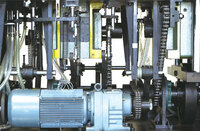

It is an intermittent full automatic capsule filling machine with multiple tamping stations, precise design and stable performance.

Following processes are completed: capsule feeding, capsule separating, powderfilling, defective capsule rejecting, capsule closing, finished capsule discharging automatically.

It adopts closed rotary table with ten stations. There are 21 holes in1 row crossing on the module.

Function of machine reaches international advanced standard, which also meets the requirement of GMP, CEand FDA standard. It’s absolutely the most ideal machine for producing capsule products.

Product INTRODUCTION

Performance

(1) Output: 3200pcs/min

(2) Change speed by transducer, PLC control(C type)

(3) Easy to operate and install

(4) Function for filling powder, pellet, granule, pellet and pill into capsule.

(5) Automatic detection and diagnosis of lack of material, capsule and mechanical trouble, make alarm and stop automatically.

(6) Displaying in-time speed and accumulative output.

(7) Available for electronic signature and recording, and Industrial Ethernet.

Machine Advantage

1. Closed turret and dosing station,preventing powder come into the turret. Easy to operate, clean and change over the mould.

2. New turret design, adopt 90 linear bearings from Japan, to guarantee machine precision and use life

3. Adopt bigger cam&dosing disk design, enhance the stability of the machine and extend the use life of the machine

4. Equippedwith oil pump forsupply lubricate oil to the cam channel, reduce abrasion and extend use life of the parts

5. Automatic capsule switch, controlled by touch screen via PLC

6. Touch screenwith used-friendly graphic operator panel.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market:

- Founded Year:1981

- Address:Headoffice: Room 2403, Tower B, Boee Building, Minhe Road No.836, Xiaoshan District, Hangzhou, Zhejiang, 310000, China Factory: Ru'ao Industrial Zone, Xinchang, Shaoxing, Zhejiang, 312500, China

- Contact:WECAPS

Other products from WECAPS

Relate products of NJP-3200C Fully Automatic Hard Capsule Filling Machine

NJP-8200 Automatic Hard Capsule Filling Machine

The hard capsule filling machine helps to increase job productivity by simplifying the five-point leveling mechanism, making it easier to clean up scattered powder. The front and rear dislocation module hole arrangement method improve powder filling accuracy, resulting in a ...

NJP-3800 Automatic Hard Capsule Filling Machine

The whole pill capsule filling machine adopts modular design, positioning pin positioning, disassembly and installation more quickly. The transmission mechanism has been optimized design so that the overall pill capsules machine is more stable, more accurate action, less ...