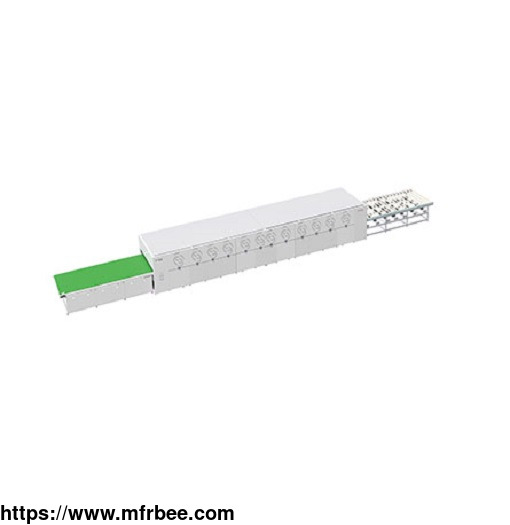

Single-layer & Double-chamber Solar Panel Laminator

Specifications

Overview

Single-layer & double-chamber solar panel vacuum laminator has one loading stage, one heating laminating stage, one cooling laminating stage, and one unloading stage.

Vacuum System and Heating System of Single-layer & Double-chamber PV Module Laminator

Vacuum System

The main component of the vacuum system is the EBRO valve. The upper chamber inflation speed is adjustable.

This system is intelligently controlled by a solenoid valve and PLC, touch screen operation and data display, and equipped with a mechanical vacuum pressure gauge and vacuum pressure sensor to

display and monitor the vacuum in the chamber in real-time.

The lamination stage is also equipped with a Pirani meter to more accurately display and monitor the vacuum state of the laminating stage.

Heating System

The heating plate adopts the processed mesoporous plate, and the flatness is ≤ 250um/㎡. The heating medium is heating oil.

The entire heating system (including the hot oil pipeline) is fully insulated, which greatly reduces heat loss and saves energy.

The selected manufacturer of the thermal oil furnace has the national TS qualification, the performance is safe and reliable.

Equipment Configuration of Single-layer & Double-chamber PV Module Laminator

Main components:

Loading stage

First laminating stage

Second laminating stage

Unloading stage

Vacuum pumps

Heating station

Solar Panel Vacuum Laminator Benefits

Improved Quality: A solar panel vacuum laminator creates a vacuum between the layers of material being laminated, which helps to remove any air bubbles and ensures a more consistent lamination

process. This results in higher-quality laminates with fewer defects.

Higher Efficiency: A solar panel vacuum laminator can operate at higher speeds than other types of laminators because it requires less time to remove air bubbles between the layers of material

being laminated. This leads to increased efficiency and higher production rates.

Lower Material Waste: The use of a solar panel vacuum laminator can significantly reduce material waste because it requires fewer attempts to achieve a high-quality laminate. This is due to the

ability of the vacuum to remove air bubbles, reducing the need for rework or scrap materials.

Improved Safety: solar panel vacuum laminators are typically designed with safety features such as interlocks and guards to ensure safe operation. They also reduce the risk of explosion or fire

hazards during the lamination process.

Increased Flexibility: A solar panel vacuum laminator can handle a wider range of materials, including thinner and more flexible materials, which can increase the range of solar panel designs that

can be produced.

For more information about solar laminator machine and solar laminator machine, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2019

- Address: No.55 Xiushui Road, economic and technological development zone,Qinhuangdao city, Hebei Province

- Contact: Jessie Wang