Medical Plastic Injection Mold

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

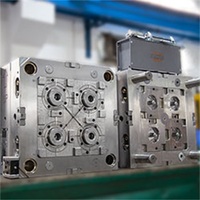

Medical Injection Mold

For medical plastic injection molding companies, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection molds

parts are designed to withstand high temperatures and chemical corrosion. In this way, it can handle frequent sterilization cycles and any other medical or bodily fluids that come into contact with

it.

INJECTION MOULDING MEDICAL PRODUCTS

Medical Pipette Tip Mold

As a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.

Multi Cavity Medical Mold

Medical equipment products are divided into many different types, some products do not contact the human body, some contact the human body, some enter the body, and some products need to pass the

FDA Alcohol test, some have to pass the FDA n-ethane test.

Medical Mold Injection Product

Medical devices have strict standards for molds, mainly involved in mold design, mold steel, manufacturing accuracy, sanitary production conditions, and transportation condition and many other

aspects.

Medical TPE Mold

Since the establishment of the factory, USM has provided custom plastic injection molding products and injection mold services for many medical companies around the world, especially in medical

multi-cavity and small products (pipetting tips) with rich and valuable experience.

Medical Plastic Mold

Product material: PP material in medical-grade

Mold steel: S136 HRC 52-54

Mold life: 1 million

Hot runner brand: Incoe

Mold base: LKM

Surface finishing: Mirror polishing

Mold lead time: 6 weeks

Medical Injection Molds Advantages

1. Medical injection molds are versatility

2. Medical injection mold is easy to disinfect

3. Higher security

4. Injection molding medical products improve the quality of life

5. High-cost performance

6. Environmental protection

7. Medical device injection molding has potential for future innovation

Medical Device Plastic Injection Moulding Application

1. Patient care series

2. Diagnostic equipment series

3. Drug filtration series

4. Shell and component series

5. Disposable medical supplies series

6. Surgical instrument series

7. Orthopedics product series

8. Heart product series

9. Ophthalmology treatment instrument series

10. Healthcare components and equipment series

The medical device plastic injection molding parts are highly specialized and precise, and have precise and detailed requirements for sterility and supervision, these requirements are much higher

comparing other industries. A dust-free injection molding shop can help ensure that particulate matter, that is dust, airborne organics, or vaporized particles will not contaminate the plastics

that will make up medical device injection molding components.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2017

- Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, China

- Contact: usm mold