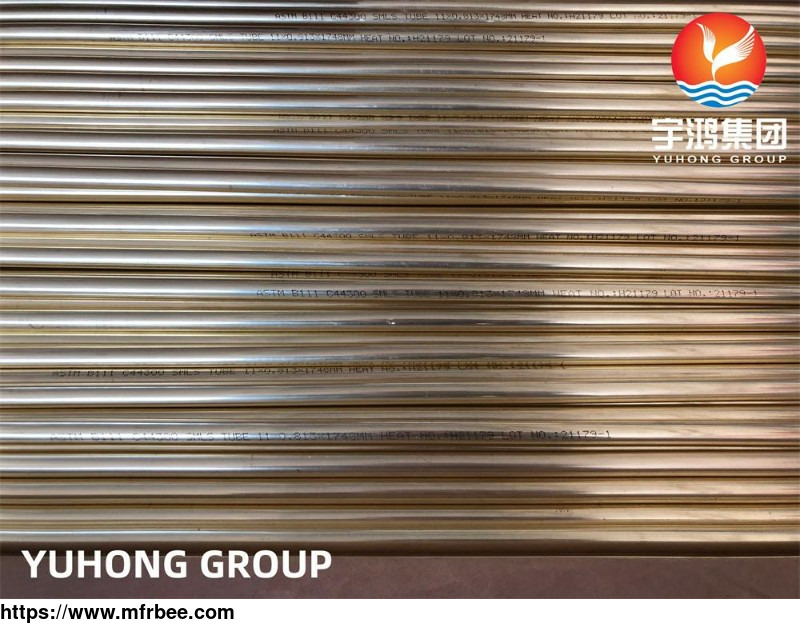

C44300 COPPER ALLOY STEEL TUBE

Specifications

C44300 Copper Alloy Pipe

ASTM B111 C44300 tube is widely used in the surface condenser, heat exchanger, and evaporators. The C44300 tube offers high strength, excellent corrosion resistance, and good creep resistance at

elevated temperatures.

SB111 C44300 TUBE SPECIFICATION

COUNTRY STANDARD NAME

ASTM ASTM B111 Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

GB/T GB/T8890 Seamless Copper Alloy Heat Exchanger Tubes

BS BS2871 Copper and Copper Alloys Tubes

JIS JIS H3300 Copper and Copper Alloy-Seamless Pipes and Tubes

DIN JIS H3300 Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers

SB111 C44300 TUBE CHEMICAL COMPOSITION

Composition Elements

Cu(1) Pb Sn(2) Zn Fe As

(1)CU+ Sum of Named Elements 9.69 min.

(2)For tubular produts the minimum Sn content may be 0.9%

Min (%) 70 0.8 0.02

Max (%) 73 0.07 1.2 Rem 0.06 0.06

SB111 C44300 TUBE PHYSICAL PROPERTIES

Melting Point- Liquidus°F 1720

Melting Point. Solidus °F 1650

Density lb/coin. at 68°F 0.308

Specific Gravity 8.53

Electrical Conductivity% IACS at 68°F 25

Thermal ConductivityBtu/sq ft/ ft hr/°F at 68°F 64

Coefficient of Thermal Expansion 68-57210 to -6 power per °F (68- 572*F) 11.2

Specific Heat CapacityBtu/lb/F at 68°F 0.09

Modulus of Elasticity in Tensionksi 16000

Modulus of Rigidityksi 6000

SB111 C44300 TUBE HIGHLIGHTS

SB111 C44300 material has the following benefits: Durability – The structure and chemical composition of an SB111 C44300 make it durable. This kind of ASTM B111 tube can last up to 10 years,

depending on where you are using them and the frequency of use.

WHAT IS THE DIFFERENCE BETWEEN SB111 C44300 TUBE AND THE SB111 C70600 PIPE?

The main difference between the SB111 C44300 tube and astm b111 c70600 lies in the material composition and their specific applications. Here are the key distinctions:

SB111 c44300 and c70600 Material Composition:

SB111 C44300 Tube: C44300 is a copper alloy pipe known as Admiralty Brass, which primarily consists of copper (Cu) with small amounts of zinc (Zn) and trace elements. It is a non-ferrous alloy with

good corrosion resistance and excellent thermal conductivity.

SB111 C70600 Pipe: C70600 is a copper-nickel alloy known as 90/10 Copper-Nickel, which contains approximately 90% copper (Cu) and 10% nickel (Ni). It also includes small amounts of other elements

such as iron (Fe) and manganese (Mn). This alloy offers high resistance to corrosion, particularly in marine environments, and has good mechanical properties.

C44300 and C70600 tubes Applications:

SB111 C44300 Tube: C44300 tubes are commonly used in heat exchangers, condensers, and other applications where efficient heat transfer and resistance to corrosion are required, such as heat

exchanger pipes. They are suitable for use in both freshwater and seawater environments.

SB111 C70600 Pipe: C70600 pipes, due to their excellent corrosion resistance, are widely used in marine applications such as seawater cooling systems, shipbuilding, and offshore installations. They

are specifically designed to withstand the harsh conditions of saltwater environments.

C44300 and C70600 Mechanical Properties:

SB111 C44300 Tube: Admiralty Brass (C44300) has good formability, making it easy to bend and shape during installation. It possesses moderate strength and can handle moderate pressures and

temperatures.

SB111 C70600 Pipe: 90/10 Copper-Nickel (C70600) has higher strength compared to Admiralty Brass. It exhibits good mechanical properties, including high tensile and yield strength, making it

suitable for applications requiring higher pressure and temperature ratings.

It is important to consider the specific requirements of the application, including the operating conditions, fluid characteristics, and corrosion resistance needed, when selecting between the

SB111 C44300 tube and the SB111 C70600 ss pipe. Consulting the appropriate specifications and guidelines for the intended use is crucial to ensure the optimal choice of material.

WHAT ARE THE BENEFITS OF SB111 C44300?

SB111 C44300, also known as Admiralty Brass, offers several benefits in various applications:

Corrosion Resistance: C44300 exhibits excellent resistance to corrosion, making it suitable for use in both freshwater and seawater environments. This property ensures the longevity and reliability

of components made from this alloy.

Thermal Conductivity: Admiralty Brass has high thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers, condensers, and other applications where

effective thermal management is crucial.

Formability: c44300 tube is highly formable, making it easy to bend and shape during installation. This property facilitates the manufacturing process and enables the creation of intricate designs

and configurations.

Reliability: Components made from SB111 C44300 are known for their durability and reliability. The alloy's mechanical properties provide sufficient strength and resistance to withstand moderate

pressures and temperatures.

Cost-Effectiveness: Admiralty Brass is often considered a cost-effective choice due to its availability, relatively low material cost, and ease of fabrication. This makes it an attractive option

for various industries.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Oceania

- Address: Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact: YUHONG .com