NICKEL ALLOY STEEL PIPE /TUBE

Specifications

NICKEL ALLOY STEEL PIPE /TUBE

Nickel alloy is one of the most useful materials for manufacturing technically superior nickel alloy pipe for industrial applications. Their inherent properties make them viable for a wide range of

uses. Nickel alloy is exceptionally corrosion-resistant and can be used in high-temperature environments.

As nickel alloys are so ductile, they are very effectively machined to produce stainless & nickel alloy piping products, while retaining strength. This makes nickel titanium alloy pipe good for use

in heat exchangers in chemical processing, for example, which relies on tubing that can withstand both the hot and corrosive environment. Nickel alloy tubes and pipes are also used in steam

generators, aircraft systems, and in oil and gas extraction. As a professional nickel alloy pipe manufacturer in China, Yuhong Group provides quality stainless and nickel alloy piping products at

great prices. Feel free to contact us at any time!

Nickel Alloy Pipe/Tube for Sale

Nickel Alloy Steel Pipe /Tube

Nickel alloy pipes are excellent for heat exchangers in the chemical processing and nuclear industries. They exist in steam generator tubing in the nuclear power industry, in high-temperature

aircraft systems, and in oil and gas extraction programs where corrosion-, pressure- and temperature-resistant tubing is required. The corrosion resistance of nickel tubing also makes them useful

in desalination.

How Does Nickel Alloy Steel Pipe/Tube Work?

Nickel Alloy Pipe and Tube include Corrosion Resistant Alloy and High-Temperature alloy, Wear Resistant Alloy, Shape Memory Alloy, and Nickel Precision Alloy. ASTM B163 B165 B167 B395 B407 B423

B444 B705 N04400 N06600 N06601 N06625 N06690 N08800 N08810 N08811 N08825 N08020 N08367 N08028 N06985 N06022 N10276.

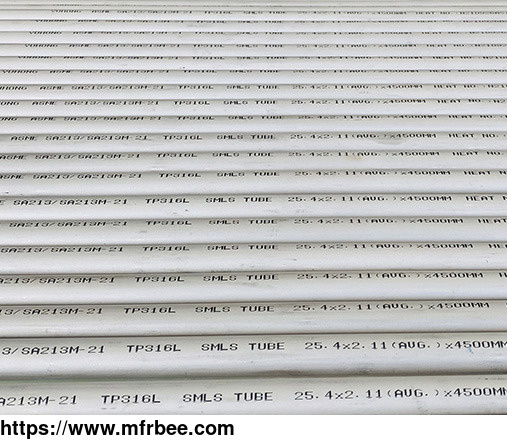

Each of the high nickel alloys described below has unique characteristics which should be considered prior to purchase. As a professional nickel alloy pipe supplier, Yuhong Group provides quality

custom stainless and nickel piping solutions. All of our Nickel Alloy Tube is seamless and cold drawn/rolling to size, and finished in bright annealing/Pickled and Annealed. custom manufactured to

your specifications, and can be manufactured in lengths up to 60′.

NICKEL ALLOY STEEL PIPE /TUBE PROPERTIES

Nickel alloy ss pipes & tubes can be manufactured using many of the key technical nickel alloys that Corrotherm stocks. For example, INCONEL alloy 625, which is a blend of nickel, chromium, and

molybdenum, offers a high-strength pipe or tube that can resist even highly corrosive environments. Due to its unique properties, it is often used in aerospace and marine applications, nuclear

reactors, pollution control plants, and chemical processing.

The MONEL range of nickel alloys can also be used for pipes and tubes. MONEL alloy 400 is a cost-effective option but can be hardened through hot or cold working to give a very durable end product.

It has been on the market for decades and is a good choice for marine applications due to its resistance to seawater corrosion. It can also be used for heat exchanger piping and rocketry uses.

Commercially pure nickel pipes, such as those made with Nickel alloy 200, contain at least 99% nickel and are useful in situations where it's important to maintain product purity, such as in the

food production industry. Nickel alloy pipes also have good thermal, electrical, and magnetostrictive properties.

NICKEL ALLOY PIPE SPECIFICATION

ASTM Specification B161, B163, B165, B167, B407, B444, B464, B468, B514, B619, B622, B626, B674, B704, B705, B725, B729, B730

Material Grade N06022, N10276, N06455, N06635, N06200, N06030, N06035, N06002, N10003, N04400, N06600, N06601, N06617, N06625, N06690, N08800, N08810, N08811, N08825,

Standard ASTM, ASME, AISI, JIS, EN, DIN......

Type of Processing Seamless, Welded(ERW, EFW)

Pipe End Plain End, Bevel End,

Technique Cold drawn, Cold rolled, Hot rolled, Extrusion Tube

Value Added Service Cutting, Beveling, Threading, Polishing,(Electric & Commercial), Bending, Draw, Expansion, Hytrostatic test, Non Destructive Test, Ultrasonic test, Annealed, Pickled

Packing End capped, Plywooden case, Woven bag bundle

Application Heat exchanger, Steam generator, Oil and gas, Petrochemical, Aircraft system, Chemical processing, Marine, Mining

NICKEL ALLOY STEEL PIPE /TUBE USES

Nickel alloys are the most outstanding and useful materials in the manufacture of pipes and tubes for industrial applications. Their inherent properties make them versatile. Nickel alloys are

particularly resistant to corrosion and can be used in high-temperature environments. Because nickel alloys are highly ductile, they can be processed very efficiently into pipes and tubes while

maintaining the corresponding strength. This makes them ideal for heat exchangers in chemical processing. Nickel-based tubing is also used in steam generators, aircraft systems, and oil and gas

extraction.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Oceania

- Address: Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact: YUHONG .com