Spark Detection And Extinguishing System

Specifications

Fires and explosions are often caused by sparks in industrial production, resulting in significant loss of life and property. During the production or handling of flammable materials, fires and explosions are often generated on air ducts, cloth bags, sanding, planers, drying, hoppers and screw conveyors. The sparks that cause most fires are most likely to be generated during automated production processes and the transport of dust.

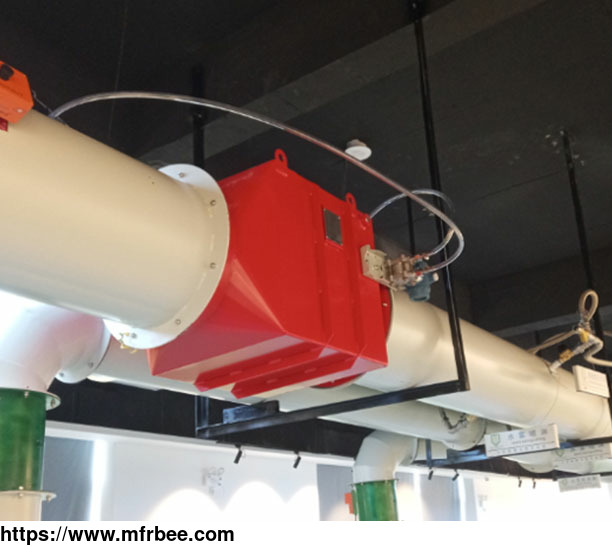

As an active fire and explosion protection device, the Spark Detection and Extinguishing System is the best solution to the above safety problems, which can detect and extinguish sparks in process equipment or pipelines in time to eliminate potential fires and explosions Danger.

Working Principle Of Spark Guard Industrial Safety Accessory

Spray the mouth for 3 seconds, enough time to extinguish the burning particles. The monitoring station is composed of a spark detector for monitoring in the downstream direction of the fire extinguishing assembly; when the spark is not extinguished, an alarm will be triggered to stop the fan and/or close the air duct valve.

The Importance of Spark Detection in Dust Collectors

Fire Prevention: Sparks generated during industrial processes, such as grinding, welding, or cutting, can ignite combustible dust particles suspended in the air. Spark detection systems swiftly identify these sparks, triggering preventive measures to extinguish them before they can ignite a fire or explosion.

Explosion Protection: In environments where combustible dust is present, such as woodworking shops or grain handling facilities, the accumulation of dust can create an explosive atmosphere. Spark extinguishing system help mitigate the risk of explosions by detecting sparks and initiating countermeasures to prevent ignition and dispersal of the dust cloud.

Equipment Protection: Dust collectors are essential for maintaining clean air in industrial facilities, but they can also be susceptible to damage from sparks. spark detection system for dust collector helps protect expensive dust collection equipment from damage by detecting sparks before they can reach the filtration system or other sensitive components.

Worker Safety: By preventing fires and explosions, dust collector spark detection systems help ensure the safety of workers in industrial environments. By minimizing the risk of catastrophic events, these systems contribute to a safer workplace and reduce the potential for injuries or fatalities.

For more information about what is villo and industrial dust removal equipment, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2007

- Address: Building B3,#1 Junma Road, Humen Town

- Contact: VILLO com