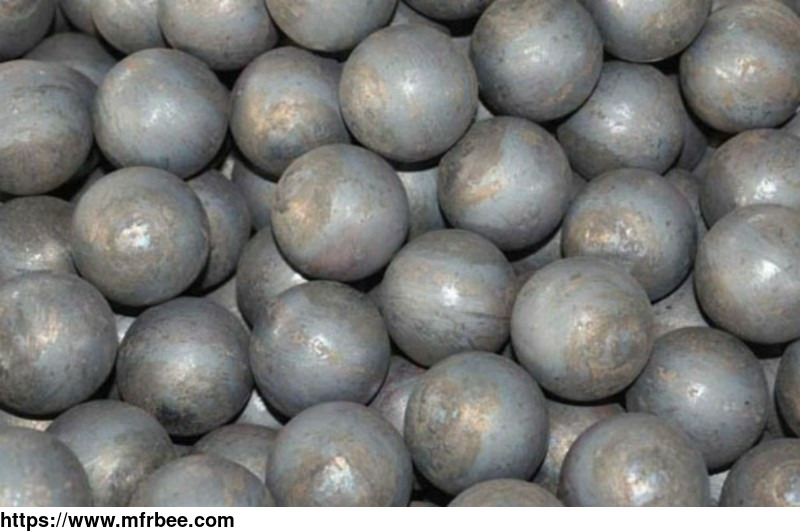

Rolled grinding ball

Product Quick Detail

- Minimum Order

- 26

- Place Of Origin

- China (Mainland)

- Packaging

- 1ton/bag

- Delivery

- 15 Days

Specifications

Compared with forged steel balls, rolled steel balls have higher production efficiency, high degree of automation, and reduce the number of manual operations. They have the characteristics of high overall hardness, compact structure, no loss of roundness, no breakage, no deformation, and high cost performance. .

1.Product specifications: Φ20-150mm

2.2. Application fields:Various metal mines (gold mines, copper mines, iron ores, molybdenum mines, alumina mines), cement plants, power plants, steel slag plants and other grinding industries.

3. Product Introduction:The Rolled Grinding balls produced by Hanfeng Grinding Balls are made of high-quality steel materials from well-known domestic steel companies, and are rolled by the company's fully automated production equipment. They have precise dimensions, round geometric shapes, high hardness and good mechanical properties. It has excellent quality of wear resistance, no deformation and no cracking.

4. Technological process:Raw material inspection - intermediate frequency furnace heating - rotary cutting into balls - quenching treatment - tempering treatment - testing - packaging

5. Product Features

1. The breakage rate is less than 1%, and the breakage resistance is more than 1.5 times that of casting balls.

2. High impact toughness: the impact toughness is greater than 15J/cm2.

3. The overall hardness is high: the surface hardness is 55-65HRC, the volume hardness is 58-63HRC, and the hardness gradient is evenly distributed.

4. No deformation: the steel ball will never deform or lose its round shape.

5. The structure is dense, the cost performance is high, and the cost saving is obvious.

6. Quality inspection

1. Hardness testing;

2. Impact test;

3. Metallographic flaw detection;

4. Pull the heart to test the hardness of the heart.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Europe

- Founded Year: 2018

- Contact: walter liu