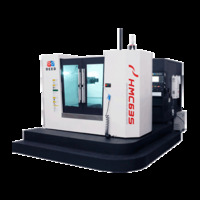

HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER

Product Quick Detail

- FOB Price

- USD $30,000.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 90 Days

Specifications

DEED horizontal machining center with pallet changer mainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcycles, especially auto engine shell, reducer shell,

mold, and general machinery industries. Our horizontal machining center for sale is at a good price. Contact us for competitive DEED CNC HMC machine price now!

Technology Upgrade of horizontal machining center with pallet changer

Deed CNC introduces its cutting-edge horizontal machining center with pallet changer, revolutionizing manufacturing efficiency. This innovative system markedly enhances production capabilities by

allowing simultaneous machining on one pallet while loading and unloading workpieces on another. This intelligent design minimizes machine downtime and optimizes the machining center's throughput.

The pallet changer system plays a pivotal role in elevating production efficiency. By facilitating seamless workpiece pre-loading and unloading during the machining process, it mitigates the need

for manual intervention, thereby reducing the risks associated with human errors. Moreover, this automation significantly contributes to the reduction of part processing cycle times, amplifying

overall productivity.

The benefits extend further, as the pallet changer system also empowers the horizontal machining center with pallet changer with heightened adaptability. It accommodates a diverse range of

workpiece types and sizes, fostering a greater degree of production versatility. This adaptability not only streamlines the transition between different tasks but also optimizes the use of the

machining center's capabilities.

Embracing Deed CNC's horizontal machining center with pallet changer represents an investment in seamless automation, precision, and productivity. By maximizing machine utilization, minimizing

idle periods, and reducing the need for manual interventions, this advanced system stands as a testament to Deed CNC's commitment to shaping the future of manufacturing technology.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Middle East,Americas

- Founded Year: 2008

- Address: North of Yong'an Road, Industrial Development Zone, Yanzhou District, Jining City,Shandong Province

- Contact: deed machinetool