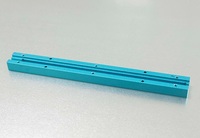

Custom Metal Machining Parts

Specifications

Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more.

Our teams are able to manufacture custom aluminium parts via our precision manufacturing machine such as 3,4, and 5 axis CNC machining centers on 2D and 3D CAD drawing from the clients. Regardless of whether you are in search of precision plastic, CNC aluminum, stainless steel parts, our production lines are able to a wide range of precision plastic or metal machining parts.

Packson also provides a free quotation and discuss the most efficient and suitable machining process for your project. Don\'t hesitate to contact our team.

Metal Machining Parts Details And Options

Applications of metal machining parts

The prototype and production of CNC metal machining have been applied everywhere. It makes possible to create anything from the automotive industry to the medical field. This means we can characterize the applications of CNC machining in various fields.

Aircraft Fields:

The history of CNC machining is long-standing in the aerospace industry. Aircraft metal machining parts are processed with the greatest accuracy. This is vital for safety-sensitive applications. In addition, the CNC-compatible engineering metal line offers aerospace engineers many options. It is wide and reliable for the applications of CNC machining in the aerospace industry. Such as landing gear components, fuel flow components, engine mounts, and fuel access panels.

Automotive Fields:

The CNC milling machine is regularly used by the automotive industry in prototyping and production. The extruded metal can be machined into cylinder blocks, gearboxes, valves, spindles, and other components. In addition, plastic CNC machinery in components like instrument panels and gas gauges. In the automotive industry, CNC machining also helps in the creation of special metal machining parts. Different spare parts can also be created using CNC. This is due to the fact that processing times are quick and there is no minimum amount of parts required.

Healthcare fields:

CNC processing can be used on a variety of medical safety materials. As the process is adapted to single customized parts, it has numerous applications in the medical sector. Our precise machine guarantees tight tolerances. It is essential to the high performance and strict requirement of medical metal machining parts. Such as electronic enclosures, implants, orthotics, and surgical instruments.

Characteristics of Packson\'s steel machining parts

Fast-Development:

Full-featured CNC design software and a qualified engineer make it possible to collect samples in 7 to 10 days.

Quick Quotation & Feedback:

From prototypes to final parts, we provide quick quotations and feedback with 1-24 hours for our clients.

Quality Control :

A complete set of inspection and quality control equipment makes great CNC machined products.

Massive Production Capacity :

Designing prototypes in wide fields and mass production of CNC metal machining parts.

Always On Time:

An accurate shipping process and a good warranty provider, we always deliver goods on time.

Advanced Equipments & Techniques:

With advanced CNC processing techniques ( Turning, Drilling, Milling) and precise equipment in Packson, we are able to produce a variety of stainless steel machined parts with high precision.

If you need any kinds of injection molding in china, please contact us, as a professional clean room injection manufacturer, Packson Mold is willing to offer you high quality products.

- Country: China (Mainland)

- Address: No.2 Building,Rongtong Industrial Park,Wulian Village,Fenggang Town,Dongguan,China

- Contact: Packson .com