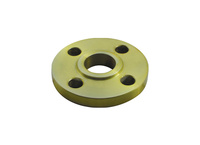

Flanges

Specifications

Flanges

Industrial ansi flanges for sale are a part used for connections between the ends of tubes or used at the entrance and exit of equipment for connections between two devices. A flange connection is

a detachable connection connected by a combination of flanges, gaskets, and bolts as a set of combined sealing structures. Flange on sales have holes in its eyes, and the bolts keep the two flanges

close together. The flanges are sealed with a gasket and flanges are used in pairs. Different flange types' thickness varies from different pressure, and the bolts used are different accordingly.

Pumps and valves, when connected to pipes, are also made into corresponding flange shapes at connection parts. As one of the professional flange manufacturers and flange suppliers, we provide

high-quality and different types of flanges for sale.

Different Flange Sizes & Standards

1)ANSI/ASME B16.5 Size: NPS 1/2"-24"

2)ANSI/ASME B16.47 Series A(MSS SP-44) Size: NPS 26"-60"

3)ANSI/ASME B16.47 Series B(API 605)Size: NPS 26"-60"

4)ASME B16.36 Size: NPS 1"-24"

5)DIN Standard Size: DN10-DN4000

6)BS 4504 Size: DN15-DN2000

7)BS 10 Size: DN10-DN3000

8)JIS B2220 Size: 10A-1500A

9)UNI Standard Size: DN10-DN2000

10)EN 1092-1 Size: DN10-DN400

Materials Used by Leading Flange Types

01

Carbon Steel: A105, RST37.2, C22.8, P235GH, P265GH, S235JR, A37, A42, etc.

02

Stainless Steel: F304/F304L, F316/F316L, F321, F44, F55, etc.

03

Other Alloy Steel: A350 LF2 F52/F60/F65/F70, etc.

Flanges Manufacturing Process

Casting

The blank size of a casting flange is accurate, so it enjoys little processing volume. The advantage of castings is that they can produce more complex shapes and have a lower cost. But casting

flange types have more casting defects (pores, crack), the internal organizational structure of the casting flanges is worse.

Forging

Let's take a look at the production process for forging flanges:

The forging process is generally composed of the selection of high-quality billet material, heating, forging, cooling. Forging methods include free forging, mold forging. When producing, forging

methods are selected according to the size and the number of flanges to be produced.

The advantage of forged flanges for sale is that the internal organization structure is uniform, and there are no pores, impurities, and other harmful defects;

Forged flanges can withstand higher shear and tensile forces than casting flanges.

The disadvantage is that forged flanges cost much more than casting flanges.

Cut Flanges

This method is to directly cut out the outer diameter of the flanges on the steel plate with suitable thickness, and then process the bolt holes and water lines. The maximum diameter of such

flanges is limited to the width of the steel plate. The advantage of this method is low cost and the disadvantage is that only plate/blind flanges can be made by this method.

Now the flanges price is reasonable, if you have needs, please contact us.

We can also offer kinds of stainless steel buttweld fittings for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading