Platinum Catalyst

Specifications

Platinum Catalyst

BTL Platinum catalyst is a chemical used for the production of many organic compounds, such as polymers, pharmaceuticals, and polyolefins. It is one of the most popular catalysts used in the

chemical industry due to its superior selectivity and activity. The BTL Platinum catalyst is a mixture of a metal, such as platinum, and a support material, such as alumina, that facilitates the

chemical reactions required to make a desired product. BTL Platinum catalyst is used in a variety of industrial processes, such as hydrogenation, oxidation, and polymerization. Its ability to

produce the desired product with minimal waste and at a lower cost makes it a popular choice for many industries.

Types of Platinum Catalyst

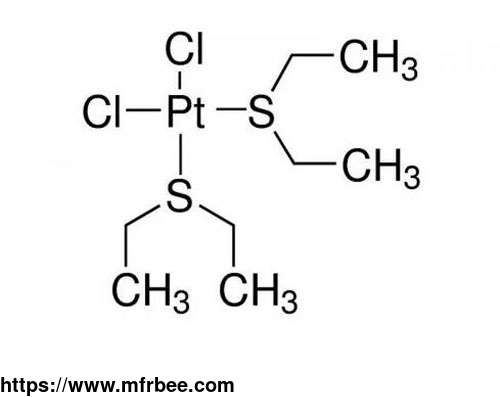

Cis-Dichlorobis (Diethylsulfide) Platinum (II)

Platinum Catalyst CAS No. 68478-92-2

Trimethyl (Methylcyclopentadienyl) Platinum (IV) -99.95%

Investigating the Properties of Platinum Catalysts

BTL platinum catalysts are a type of catalyst used in a wide range of chemical reactions. They are especially useful in hydrogenation and dehydrogenation reactions, as well as some other organic

and inorganic syntheses. Platinum catalysts are composed of platinum, palladium, and/or rhodium. They are known for their ability to increase the rate of reaction and improve the selectivity of the

reaction, making them a highly sought-after material in many industries. Platinum catalysts including PTO2 catalyst are highly efficient and have a long lifespan, making them an attractive choice

for industrial processes. They also require less energy than other catalysts, making them a cost-effective option. Platinum catalysts are also highly resistant to corrosion and can be used in

extreme temperatures and pressures. Their unique properties make them valuable asset for many industries, and research is ongoing to further understand and improve their performance.

How platinum catalysts work in industrial applications?

Platinum catalysts, produced by BTL, are widely used in industrial applications to facilitate a variety of chemical reactions. Platinum catalysts are typically made up of platinum nanoparticles

dispersed on a carbon support material. The platinum nanoparticles act as active sites for chemical reactions, increasing the reaction rate and improving product selectivity.

The most common industrial application for BTL platinum catalysts is in the production of fine and specialty chemicals. This includes the production of pharmaceuticals, plastics, and synthetic

fuels. Platinum catalysts can also be used in the production of commodity chemicals, such as ethylene and propylene.

In addition to their use in chemical reactions, platinum catalysts can also be used to purify air and water. Platinum can be used to reduce the emissions of pollutants, such as NOx, CO, and SOx,

from industrial processes. It can also be used in water treatment systems to reduce the levels of heavy metals, volatile organic compounds, and other contaminants.

BTL platinum catalysts are highly effective, durable, and cost-effective. They can also be easily customized to meet the unique needs of each application. With their versatile applications, BTL

platinum catalysts are an essential component of many industrial processes.

As one of platinum catalyst suppliers, we will do our best to meet all the needs of customers.

If you are looking for a reliable silicone factory china, please choose us, and we will be your best partner.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Europe,Americas

- Founded Year: 2000

- Contact: betely