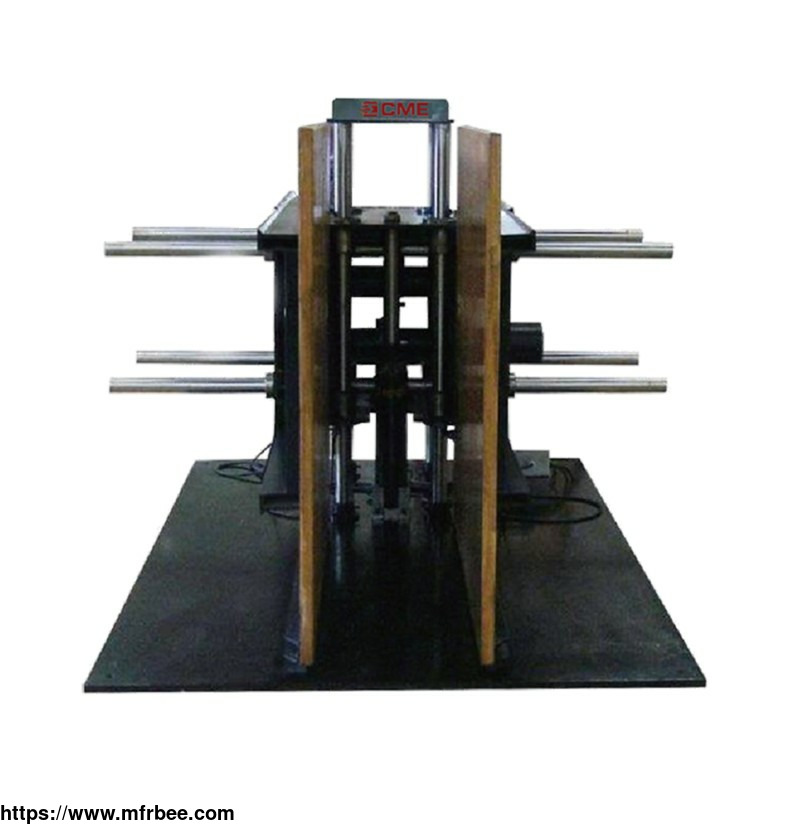

KRD102 Clamping Force Tester

Specifications

KRD102 Clamping Force Tester

KRD102 series clamp force tester is newly developed multi-functional economical carton quality inspection equipment, mainly used for household appliances, furniture, toys, kitchenware and other

finished packaging to do clamping test. It can simulate the situation of goods being clamped from the container to the warehouse, whether the goods are damaged due to clamping, so as to evaluate

the ability of packaging to resist clamping.

The clamping force tester is an indispensable testing method for improving products to leap into the high-quality field. It is suitable for the research, development, and product development of

various industries such as electronics, electromechanics, optoelectronics, automobiles, toys, and packaging. It can meet ASTM D6055, American SEARS corporate standards, and can also be non-standard

customized according to the different needs of customers.

FEATURES OF KRD102 CLAMPING FORCE TESTER

PLC-based stable control system: fully automatic remote control touch screen interface

Automatic man-machine interactive control, high accuracy, good repeatability

Full hydraulic drive, simple structure, and high reliability

Servo valve control pressurization system: improve the pressure control accuracy, and complete the test with higher requirements

High accuracy, good repeatability, and height measurement is completed by the displacement sensor

Reliable pressure testing system: using high-precision pressure sensors, high precision, and good reliability, to ensure the accuracy of the test

COMPOSITION OF KRD102 CLAMPING FORCE TESTER

KRD102 clamping force test system mainly includes a clamping force testing table, hydraulic drive system, hydraulic proportional servo system, and electrical control measurement system.

The clamping force testing table is mainly composed of a specimen clamping plate, a guide shaft, a clamping movement cylinder, a vertical movement cylinder, a clamping sensor, a displacement

sensor, a hydraulic oil source, etc.

The control system sends the set data signal to the proportional servo amplifier to control the corresponding electro-hydraulic proportional servo valve. The electro-hydraulic proportional servo

valve is supplied with pressure from the hydraulic source system to push the hydraulic drive system to drive the movement of the splint to generate the corresponding clamping force.

If you want to know more kinds of packaging materials testing equipment, please visit our website.

CME mechanical environment testing equipment covers wide range of testing, including shock test, vibration test, constant acceleration test, drop test, incline impact test, compression test,

whatever type of international standards you need to test for your products, we have the corresponding mechanical test equipment to carry out the testing.

As one of vibration shaker manufacturers, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Founded Year: 2006

- Address: No.3 Upgrade Demonstration Base, West of Yongchang Rd., High-tech Zone, Xianyang City, Shaanxi Province, 712023 China

- Contact: Echo Yang