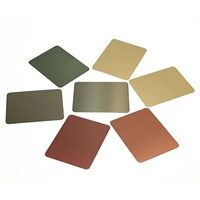

Stainless Steel Surface Finishes

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Minimum Order

- 25

- Place Of Origin

- Foshan, Guangdong, China.

- Packaging

- Export standard waterproof packaging

- Delivery

- 30-45 days

Specifications

stainless sheet metal finishes determine the final appearance and characteristics of the material. Some common surface finishes include brushed, mirror, satin, and patterned finishes. These

finishes not only improve the aesthetic appeal but also provide additional protection against corrosion and scratches.

1. Regular cleaning: stainless steel surface treatment should be cleaned regularly using a mild soap and water solution or a specialized stainless steel cleaner. This helps to remove any dirt,

grime, or fingerprints that may accumulate on the surface.

2. Proper use of cleaning tools: When cleaning a ss surface finish, it is important to use non-abrasive cleaning tools such as soft cloths, sponges, or scrubbers. This will prevent scratches or

damage to the surface finish.

3. Avoid harsh chemicals: Avoid using harsh chemicals or corrosive substances such as bleach, ammonia, or chlorine on stainless steel surfaces. These substances can damage the surface finish and

cause discoloration or corrosion.

4. Proper storage: stainless steel sheet metal finishes should be stored in a cool, dry place to prevent moisture or humidity that can cause rust or other types of corrosion.

5. Polish the surface: To maintain the shine of a stainless steel surface, it may be necessary to polish it on a regular basis. This can be done using a specialized stainless steel polish that is

designed to remove tarnish and restore the shine of the surface finish.

6. Professional maintenance: In some cases, it may be necessary to seek professional maintenance for a stainless steel surface. This may include specialized cleaning or polishing services to

restore the bead blasting stainless steel finishing or repair any damage that may have occurred.

For more information about stainless steel sheet polishing, please feel free to contact us!

If you are looking for a reliable stainless steel products company, don't hesitate to contact us!

- Country: China (Mainland)

- Founded Year: 2005/3/8

- Address: NO.39-41 2nd Floor. Central building, Lanshi International Metal Trading Centre, Chancheng District, Foshan, Guangdong, China.

- Contact: normandymetal com