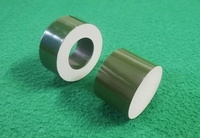

FPQ2W-10/3T20 10kV Pin Insulators

Specifications

The crimping process of polymer pin type insulators should pay attention to the crimping force, compression amount, pressing speed, holding time, etc. during crimping. Due to the cumulative error

of the size of mandrel and fittings, the maximum error can reach 0.2mm. According to experience, a compression error of 0.05 mm may cause an error of more than 10% on the crimping strength.

Therefore, the crimping process will focus on pressure, and determine the proper The crimping force; in order to reduce the influence of the mandrel and the material fluctuation of the fittings, it

is assisted to control the amount of compression; the pressing speed should not be fast, and the fittings should be fully plastically deformed during the slow pressing process, and the holding time

should not be too long , to prevent the mandrel from breaking, the best experience time is about 2s.

Specifications of FPQ2W-10/3T20 10kV polymer pin insulator

Type FPQ2W-10/3T20

Rated bent withstand load (kN) 3

Height (mm) 260

Max. diameter of insulated parts (mm) 146

Min. Creepage distance (mm) 184

Min. Nominal creepage distance (mm) 460

Downward bolt thread diameter (mm) 20

Rated voltage (kV) 10

The highest voltage of equipment (kV) 12

1min power frequency wet withstand voltage not less than (kV) 50

Full wave lightning impulse withstand voltage(peak value) not less than (kV) 110

For more information about power line hardware, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2023

- Address: No.10 Longxi Road, Nan cheng Street, Dongguan, Guangdong, China

- Contact: YF POWER POWER