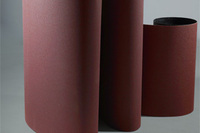

Sell Sanding Belts

Product Quick Detail

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

An abrasive belt is used in woodworking and metal work. The abrasive belt is often referred to as a sanding belt or sandpaper belt and is used to smooth out a rough surface finish. In many instances, the abrasive belt might be used to actually shape a piece or create a part from a larger piece of stock by grinding the piece to a desired size and shape. Typically fitted around two or more rubber wheels and driven by an electric motor, the abrasive belt is an important component in most work shops.

The abrasive belt is constructed by gluing rough abrasive particles onto a cloth or paper-likebelt in a circular configuration. The belt is constructed to give the operator a durable, long-lasting product to work with. The abrasive bits used on the surface of the belt are applied in differing sizes, which are known as grits. The larger the grit or number of grits given to a belt, the larger the abrasive bits on the belt. A higher grit rating also reflects a lesser number ofabrasive bits on the belt.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:F367 .NO.1 FengTai District Beijing China bjtm5899@126.com

- Contact:Gong Liu

Other products from Beijing Tong Ma abrasives Co.,Ltd

Relate products of Sell Sanding Belts

Narrow Sanding Belts for Wood Compared with the existing market products, we have applied calcined grains for longer life and long-lasting sharpness. The sand cloth not only have good performance on hardwood grinding, but also have a good grinding effect on oily and cork wood ...

This abrasive cloth backing has anti-slip treatment with high strength. CJ25 sand cloth can be converted into a narrow & semi-wide sand belt with high efficiency and perfect surface finishing. CJ25 silicon carbide abrasive cloth belt is mainly used in the polishing of Copper ...

The backing of RMC AX67 woodworking sanding belts is Xwt, which is ideal for making the abrasive belt. Calcined aluminum oxide bring good sanding performance.This sand cloth has a good effect on sanding wood, hardware, stainless steel and so on. Specification of AX67 Cloth ...