Perforated Sheet for Vibrating Screens

Specifications

Perforated Vibrating Screen Sheet Specifications

Perforated vibrating screen sheet is the best choice in unique and severe screening situations. It is made to suit the specified screening application and screening equipments.

Unlike woven wire cloth, perforated plate has a level screening surface, free from high points, which rapidly wear away in many severe screening applications. The flat screening surface and length

of the screen deck can effectively separate the over-sized sliding materials from the undersized particles.

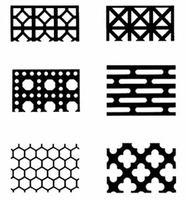

There are three hole types of the perforated vibrating screen sheet.

Square hole

A piece of square perforated vibrating screen.

Square perforated vibrating screen sheet is the most frequently used hole type.

Square hole perforated vibrating screen is the most frequently used aperture in the vibrating screens. It can be divided into staggered pattern and straight pattern. Square hole can be directly

matched to the required testing sieve openings. It can also be designed to offer the equivalent open area of wire cloth.

Different sizes for the support bars, center hold-down bars and impact areas are designed to maximize open area and increase wear-life of both the screening plate and your vibrating screen.

Square hole staggered pattern

Thickness: 16G, 14G, 12G, 11G, 10G, 3/16”, 1/4”, 5/16”, 3/8”.

Opening size: 5/32” - 9/16”.

Bar: 3/32” - 3/8”.

Square hole straight pattern

Diameter: 11G, 10G, 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”.

Opening size: 5/8” - 7”.

Bar: 5/32” - 2”.

Round hole

A piece of round hole perforated vibrating screen and several stones on it.

Round perforated vibrating screen sheet offers the most consistent sizing and least open area.

Round hole perforated vibrating screen is ideal for places where extreme accuracy is absolutely necessary, such as the screening anthracite and bituminous coal, metallic, ore, and in aggregate

screening facilities.

The round hole offer the most consistent sizing and least open areas, regardless of the shape of the incoming materials. It is also suit to aggregate screening where plugging is prevalent. The

aggregate material, which fails to pass the round openings is freely discharged due to the consistent round opening shape.

Specification

Thickness: 20G, 18G, 16G, 14G, 12G, 11G, 10G, 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”.

Opening size: 1/16” - 8”.

Bar: 3/64” - 1-3/4”.

Hexagonal hole

A piece of hex. Perforated vibrating screen.

Hexagonal perforated vibrating screen sheet is the compromise between square and round hole.

Hexagonal perforated vibrating screen has maximum open area and screening efficiency. It is the best compromise between square openings and round openings where the plugging occurs. It is also a

good choice where high production of accurately sized material is needed.

Specification

Thickness: 12G, 11G, 10G, 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”.

Opening size: 1/4” - 6”.

Bar: 1/8” - 1-1/4”.

Feature

Abrasion resistant.

Impact resistant.

High impact strength and long wear resistance.

lat screening surface and free from high points for rapidly wear away in many severe screening applications.

Applications

Perforated sheet metal plate is mainly for filtration and separation. Perforated vibrating screen has superior screen surface and great performance of filtration, so it is widely used in the

flowing industries:

Crushed Stone Quarries

Sand & Gravel Plants

Coal Preparation Plants

Phosphate Rock

Iron Ore Mines

Copper Mines

A piece of square perforated vibrating screen and a machine is on the top of it.

Square perforated vibrating screen sheet can be used in the crushed stone quarriesA vibrating cylinder and several small stones in it.

Perforated vibrating screen sheet can be rolled and welded to cylinder.

- Country: Afghanistan

- Market: Africa,Americas,Asia,Emerging Markets,Europe,G20

- Address: Industrial Park, Anping County, Hengshui City, Hebei Province, China.

- Contact: hui zhang