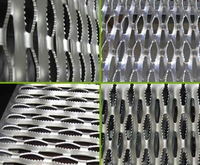

Excellent skid-resistant serrated bar steel grating

Specifications

Low carbon steel, stainless steel serrated bar grating

Serrated steel grating, or serrated bar steel grating, is made of mild carbon steel and stainless steel. Such steel grating is produced by welding bearing bars and cross bars with certain distances to form a high strength structure. The serrated surface can supply good skid resistance, hot-dipped galvanized treatment is suitable for harsh environment and the stainless steel material provides it a long life performance. Serrated steel grating is widely applied as stair treads, walkways, trench covers, etc.

Hot-dipped galvanized serrated steel grating

Features:

- Anti-skid and safe. Serrated surface increases the friction and reduces the probability of slipping.

- Anti-rust and anti-corrosion. Hot-dipped galvanized treatment is ideal for anti-rust and anti-corrosion.

- High strength and loading capacity. The strength and toughness are much better than any other iron products. It can be used for terminals, airport and large-span and heavy loading condition.

- Best drainage. It has 83% leakage area and has better drainage property.

- Durable and long life. Stainless steel material makes the grating durable and long life.

- Easy installation.

- Good ventilation.

- Anti-theft design.

Specification:

- Material: low carbon steel ASTM (A36) or Q235, stainless steel 304 or 316.

- Surface treatment: hot-dipped galvanized, electro galvanized, painted surface.

- Bearing bar thickness: 1/8", 3/16".

- Bearing bar width: 3/4", 1", 1-1/4", 1-1/2", 1-3/4", 2", 2-1/4", 2-1/2".

- Spacing of bearing bar: 9/16", 11/16", 15/16", 1-3/16", 1-3/8", 1-9/16", 1-7/8", 2-3/8".

- Bearing bar pitch: 12.5, 15, 20, 30, 30.16, 32.5, 34.3, 40, 60mm, of which 30mm & 40mm are recommended.

- Cross bar thickness: 1/4", 5/16".

- Spacing of cross bar: 2", 4".

- Cross bar pitches can be 38, 50, 60,100mm, of which 50mm & 100mm are recommended.

- Packing: packed with strips then into pallet or screw rod fixed.

| Spec. | Spacing of Bearing Bar | Spacing of Cross Bar |

|---|---|---|

| 38-W-4 | 2-3/8" | 4" |

| 38-W-2 | 2-3/8" | 2" |

| 30-W-4 | 1-7/8" | 4" |

| 30-W-2 | 1-7/8" | 2" |

| 25-W-4 | 1-9/16" | 4" |

| 25-W-2 | 1-9/16" | 2" |

| 22-W-4 | 1-3/8" | 4" |

| 22-W-2 | 1-3/8" | 2" |

| 19-W-4 | 1-3/16" | 4" |

| 19-W-2 | 1-3/16" | 2" |

| 15-W-4 | 15/16" | 4" |

| 15-W-2 | 15/16" | 2" |

| 11-W-4 | 11/16" | 4" |

| 11-W-2 | 11/16" | 2" |

| 9-W-4 | 9/16" | 4" |

| 7-W-2 | 7/16" | 2" |

| 7-W-4 | 7/16" | 4" |

| Bearing Bar Width | Bearing Bar Thickness | Cross Bar Thickness |

|---|---|---|

| 3/4" | 1/8" | 1/4" |

| 3/4" | 3/16" | 1/4" |

| 1" | 1/8" | 1/4" |

| 1" | 3/16" | 1/4" |

| 1-1/4" | 1/8" | 1/4" |

| 1-1/2" | 1/8" | 1/4" |

| 1-1/2" | 3/16" | 5/16" |

| 1-3/4" | 3/16" | 5/16" |

| 2" | 3/16" | 5/16" |

| 2-1/4" | 3/16" | 5/16" |

| 1-1/2" | 3/16" | 5/16" |

Application:

- Used for steel structure platforms, sidewalks, bridges, stair treads because of its excellent slip resistance.

- Appropriate application in industrial and civil construction such as city roads, airport, railway, gardens, yard and industrial engineering.

- Ideal for power plant, sewage treatment factories, trench cover and chemical products workshop.

Stainless steel serrated grating is anti-skid and durable as stair treads

Serrated steel grating with good anti-skid property applied as walkway in workshop

- Country: Afghanistan

- Market: Americas,Asia,Emerging Markets,Europe,European Union

- Contact: hui zhang