A480 pneumatic thermal melt strapping tool

Product Quick Detail

- Place Of Origin

- China

- Model

- A480 KZ-19/16/13

- Seal Tensile Strength

- ≥ 6.3KN

- Tensioning Stength:

- ≥ 4.9KN/0.6Mpa

- Strap Tensioning Speed:

- 5.5m/min

- Strap Width:

- 13/16/19mm(one machine suit for one size strap)

- Strap Thickness:

- 0.38-0.8mm

- Air Pressure:

- 0.42~0.6Mpa

- Strap Material:

- Steel strap

- Weight:

- 5kg

- Packaging

- carton

- Delivery

- 3 Days

Specifications

Pneumatic handheld steel strapping tool

Technical data

Mode: A480 KZ-19/16/13

Seal tensile strength: ≥ 6.3KN

Tensioning stength: ≥ 4.9KN/0.6Mpa

Strap tensioning speed: 5.5m/min

Strap width: 13/16/19mm(one machine suit for one size strap)

Strap thickness: 0.38-0.8mm

Air pressure: 0.42~0.6Mpa

Strap material: Steel strap

Weight: 5kg

Maintenance & Repair

*The problems of wearing parts, loose screw, environmental pollution, and bad lubricating probably cause the malfunction during the operation. You shall clear it promptly to make it run properly. Good attention to the maintenance will have a much longer use of steel strapping tools.

*Before every use, it shall be treated with lubricant.

*Timely remove the dust and dirt on the friction pulley.

It is pneumatic mode tools,with light weight,safe and convinent operation,strong banding power,well-locked,low labour intensity and easy to use.

It is hand operated, finish tensioning, sealing, cutting as a whole, greatly increases the packing efficiency. It is of latest design, compact and durable.

* Combined, finish tensioning, sealing

* Efficient and safe, hands protective.

* Ergonomic design, easy to operate

* Strong joint, high bonding strength.

Tool Details Photo

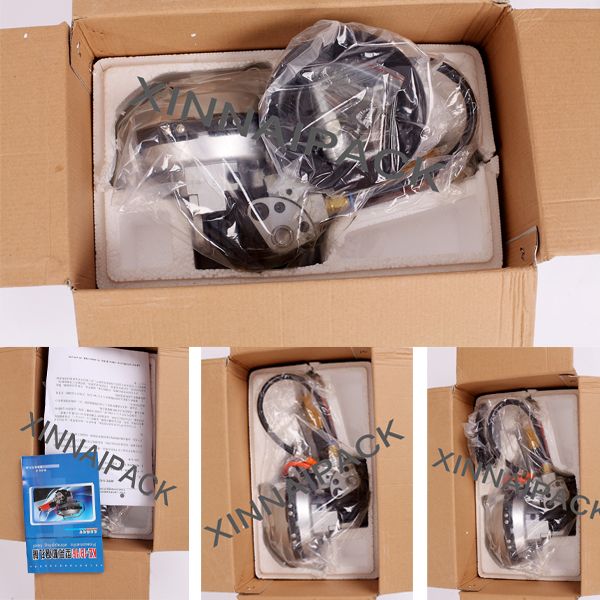

Package photos

Factory pictures

- Country: China (Mainland)

- Business Type: Manufacturer,Distributor/Wholesaler,Trading Company

- Market: Europe,Asia,Africa,Americas,Middle East

- Founded Year: 2003

- Address: 上海市松江区九亭镇高新技术开发区九泾路655号1号楼501室

- Contact: leafit Ye