Ceramic Foundry Sand

Specifications

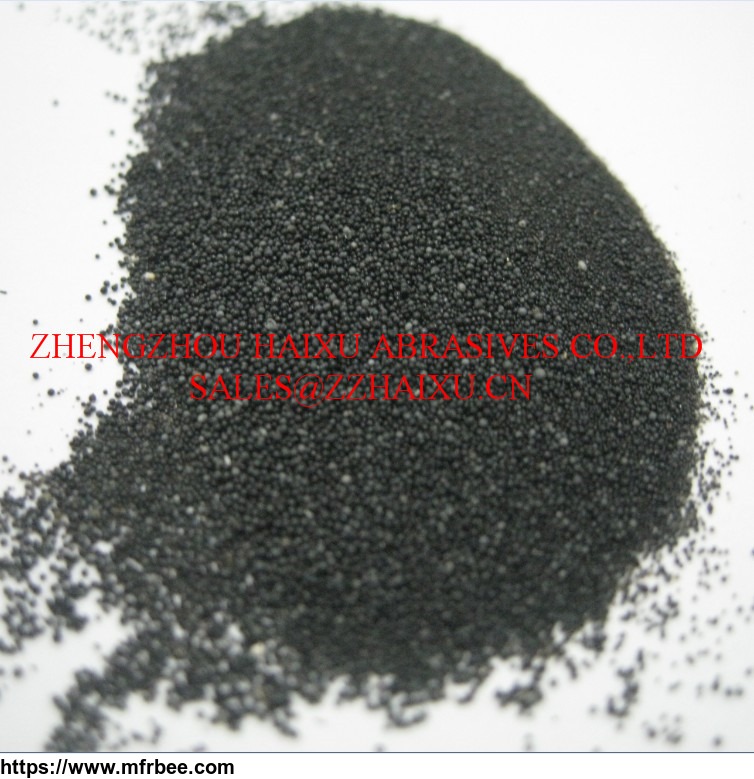

Ceramic foundry sand ,called ceramisite sand,china cerabeads and cerasand too, is made from high quality bauxite, by re-fused and blown to ball type. With advantage of fine surface smooth finish and air permeability, it is a new type casting material for precision casting, coated sand and self hardening sand etc.

Size:10-300mesh

Main Chemical Composition:

Al2O3≥75%

Fe2O3≤5%

TiO2 ≤5%

SiO2:5%-20%

Physical Properties:

Shape:ball, spherical

Angularity: 1.1 max, similar to ball

Bulk Density:1.95-2.05(g/cm3)

Refractoriness: 1790 C min

Thermal expansion: 0.13% (10 min at 1000 C )

Application:

Waterglass bonded sand, resin bonded sand, precision casting, Expendable Pattern Casting (EPC), Copper and Aluminium articles casting treatment.

Advantages:

1,replacement of Quartz Sands and Silica Sands

2,Low thermal expansion rate

3,high refractoriness

- Country: China (Mainland)

- Founded Year: 1999

- Address: 桐柏南路凯旋门A-801

- Contact: Sunshine Ma