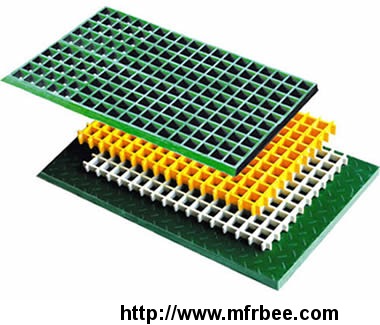

FRP Gratings

Specifications

FRP Gratings with Light Weight but High Strength

SARE Company's FRP/GRP gratings (Fiberglass Reinforced Plastic Gratings) are interwoven from glass fibers, cast resin and then molded into FRP grating plates with regularly distributed rectangle or square holes, and they have perfect bi-directional mechanical properties. FRP gratings can be widely used for the working platforms, equipment platforms, drilling platforms andwalkways of petroleum, chemical electronics, electricity, paper, printing and dyeing, electroplating, ocean exploration, sewage treatment and so on. They are the ideal choice for corrosive environments, but also can be applied to civil construction facilities.

Square-hole FRP gratings have stable structure for wide applications.

FRP gratings have various colors and different surface types according to customers' request.

Three kinds of manufacturing techniques:

- Reciprocating filament winding process.

- Continuous filament winding process.

- Centrifugal pouring process.

And nowadays, manufacturers who use reciprocating filament winding process are much more than the other two production technologies manufacturers, one of the reasons is that the FRP gratings made by the reciprocating filament winding process have a wider range of applications and better applicability.

- Country: China (Mainland)

- Address: No. 289 Zhongxin road, Anping County

- Contact: Hui Cheng