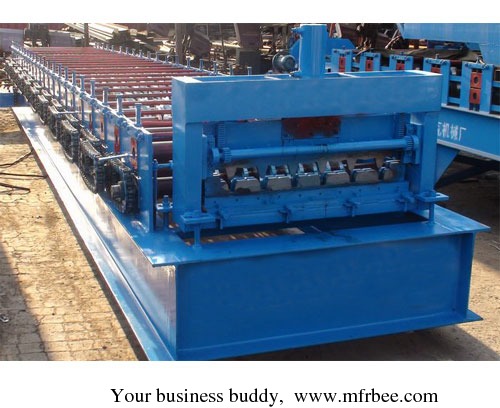

roll forming machine

Specifications

Roll forming machine, which is applied to process equipment of the sheet material can be achieved functions of curling, horizontal shear, shearing and bending machine and other functions. Roll forming machine is mainly composed of three parts: the mechanical transmission parts, pneumatic parts and electrical parts. Working principle and characteristics of the roll forming machine: Working principle of the roll forming machine: The roll forming machine consists of two squeeze rollers, which rotate synchronously in opposite position, a fixed roller and an active roller. The material is provided from the top of the two rollers, to squeeze into the roller and withstand 50 - 100 MPa high pressure. Finally, it turns to be a dense cake which is discharged from the machine. The discharged material not only contains a certain proportion of fine finished products, but also has within a large number of cracks in the non-finished particles. In the further process of crushing, it can reduce grinding energy. Between the double roll, it should have a layer of compatible materials, or it must be a roll crusher. The crushing effect is mainly determined by the pressure between the particles rather than the gap.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Africa

- Founded Year: 2010

- Address: 04 National Road, Botou City

- Contact: allen li