Polyethylene (PE) Film Flame Retardant Masterbatch

Specifications

- Product Name:

Polyethylene (PE) Film Flame Retardant Masterbatch/MH-1801

- Characteristics:

Recombination extrusion of efficient activating treatment and low tempeature plastifying

technology with halogen flame Retardant, synergist, additives and LDPE carrier.

- Advantages:

Environment-Friendly, Simplify the production technology process, Reduce the production cost, Avoid dust, Improve the working environment, Improve the production capacity, Good disperstiy, Better fire-resistant effect, High thermostability, Can process repeatly without influence of mechanical property

- Application:

Manily used for PE spinning, corrugated pipe, film, etc.

- Specification:

| Items | Index |

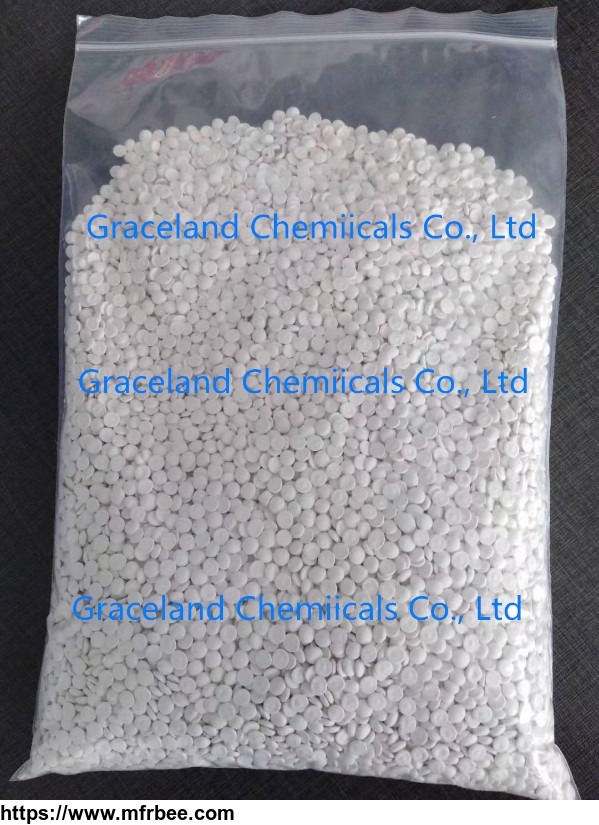

| Appearance | White or Light Yellow Granule |

| Carrier | LDPE |

| Main Content | 50% Min |

| Melting Point | 300℃min |

| Moisture: | 0.2%max |

Remark:

1.The Melt Index of the LDPE carrier is 1.5g/10min

2.The added quantity can be adjusted according to the thickness of the film. Recommendation is 12-15%.

-Package and Storage:

25Kgs kraft bag with double PE inner or by customer’s requirement. Handle with care, keep air-tight and dry

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Asia,Middle East

- Founded Year: 2008

- Address: Room 1501 Building A Wanda Plaza Weifang City, Shandong Province, China

- Contact: Mark Xu