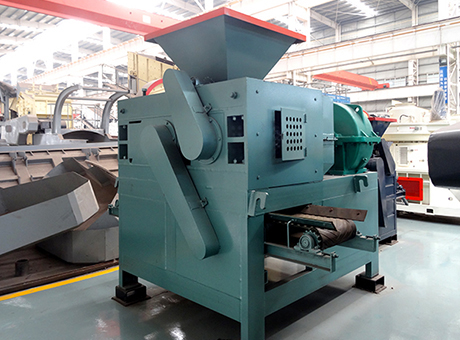

White Coal Briquetting Machine

Product Quick Detail

- FOB Price

- USD $4,300.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Within 5-25 working days after placing the orderc

- Delivery

- 15 Days

Specifications

Coal briquetting machine refers to the corn stalks, wheat straw, cotton stalks, rice straw, rice husks, peanut shells, corn cobs, twigs, leaves, sawdust and other crops, solid waste in rural areas (such as mushroom residue, funeral residue, etc.) raw material, after crushing pressure, increasing the frequency molding, production of “straw coal” machines. Coal briquetting machine using the squeeze pressure between flat and round shaped module die hole pressure and friction interaction theory, the coal obtained molding. Coal in the process without the addition of any additives or binders. Coal contains a certain amount of cellulose, the structure of the coal in the monomer, benzene propane-type polymers. Cell walls with enhanced adhesion effect of cellulose. Lignin is a non-crystalline, at room temperature, the major part of any solvent-insoluble, no melting point, but a softening point. When the temperature reaches a certain value, the softening the adhesive force increases, and at a certain pressure, so that the cellulose molecules displacement, deformation, extend inside the adjacent engagement biomass particles contact each other, to suppress recombination molding.

Malfunction of Durable Performance Coal Briquette Machine/White Coal Briquetting Machine:

1. The ball sockets are mismatched. ------- loose the adjusting blot and tight it up after adjusting it.

2. The oil pressure can’t supply. --------------take the inlet port apart and clean it. Please watch the manual operation during the process.

3. More broken materials and lower forming rate------------check the wear pattern of the triangle scale-board; adjust the feeding capacity and the oil pressure.

4. The surface of the briquettes is rough and the briquettes can’t get it off the roller easily. -----------adjust the feeding capacity and the moisture content.

5. The intensity of the finish products is not strong and the forming rate is not high. --------adjust the feeding capacity; check the oil pressure; inspect the moisture content of the feeding material.

The quality and durability of Fote briquetting production line set the standard for briquetting coal powder and other mineral powder all over the world, we deliver that same innovative technology and quality along with superior client service and support that stretches from initial consulting and process integration to on-site implementation and maintenance. As one professional briquette machine manufacturer, we can supply you the whole production line which includes briquette machine, belt conveyer, binder mixer, grinding mill, binder mixer, rotary dryer, etc. Welcome to visit our company.

Contact Information

Email: info@sinoftm.com

Website: http://www.ballpress-machine.com/p_14.html

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Asia,Middle East,Europe,Americas

- Founded Year: 1982

- Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

- Contact: Olivia Wange