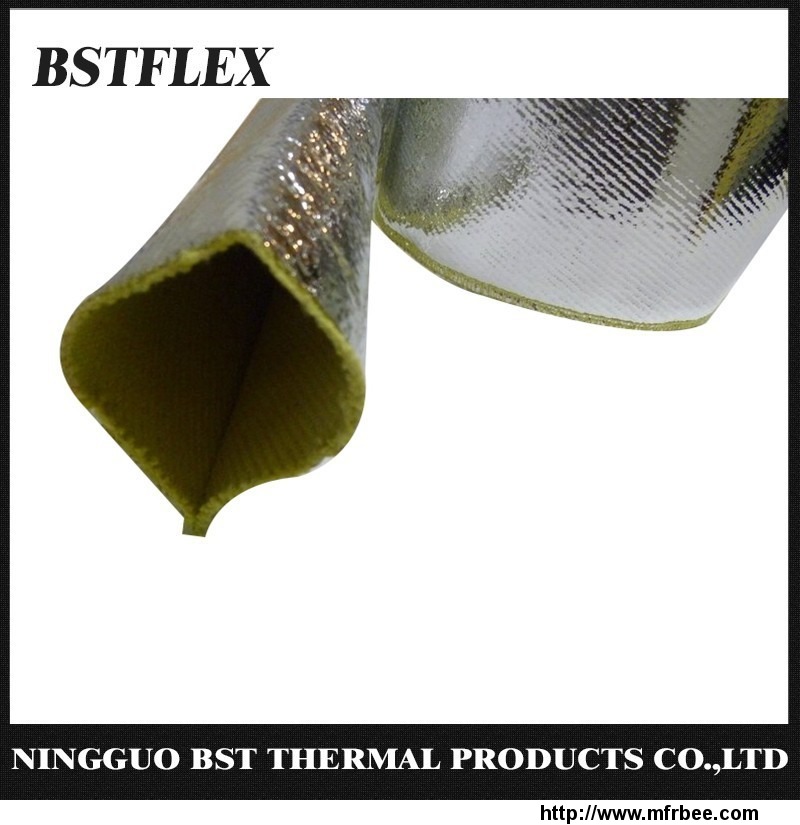

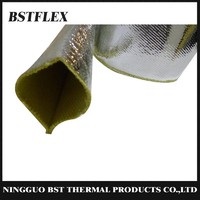

Aluminized Aramid Fiber Reflectsleeve

Product Quick Detail

- FOB Price

- USD $3.00 / Piece

- Minimum Order

- 10

- Place Of Origin

- China (Mainland)

- Packaging

- Aluminized Aramid Fiber Reflectsleeve pack carton box

- Delivery

- 3 Days

Specifications

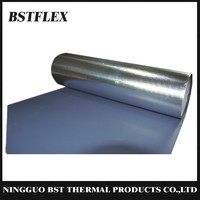

Aluminized Aramid Fiber Reflectsleeve is fabricated from Aluminized Kevlar Fiber Fabric. Aluminized Kevlar Reflectsleeve has two layers of aluminum coating and a protective film, all laminated to a

specially designed heavy grade aramid fiber cloth by means of a heat stable adhesive. The aluminum layers will not delaminate from the cloth, even under the most extreme heat conditions.

Aluminized Aramid Fiber Reflectsleeve offers continuous operating temperature protection to 500°F and short term thermal exposure to 1000°F. The sleeve reflects 90% of radiant heat energy and also

offers excellent cut resistance.

Applications for line sleeve - industrial wires -cables/hoses (hydraulics) -piping + tubing from radiant heat sources; such as liquid metal pour steam, glowing steel slab, infared heaters, open

flame/plasmas or engine exhaust manifolds

Aluminized Aramid Fiber Reflectsleeve is also offered reversed upon request - Kevlar on the outside for severe abrasion-type applications. With reversing the sleeving, it offers good thermal

protection and excellent cut-through protection.

Aluminized Aramid Fiber Reflectsleeve quick facts

| Continuous operating temperature | 650°F (343°C) |

| Max short term exposure | 1000°F (538°C) |

| Molten splash resistance | Outstanding |

| Weld spatter resistance | Outstanding |

| Flame resistance | Outstanding |

| Abrasion resistance | Outstanding |

| Flexibility | Outstanding |

| Water and oil resistance | Outstanding |

- Country: China (Mainland)

- Business Type: Manufacturing & Tracding Combo

- Market: Americas

- Founded Year: 2012

- Address: Anhui Ningguo 1# Jiajia Area

- Contact: Gemini Huang