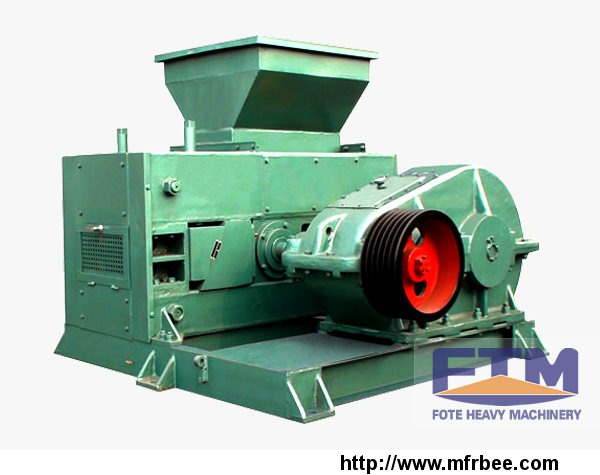

Stable Performance High Pressure Coal Briquette Machine

Product Quick Detail

- FOB Price

- USD $3,300.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard export containers, bare main machine, motors and small parts are packed in wooden cases.

- Delivery

- 15 Days

Specifications

High pressure briquette machine is widely used to make briquettes from various dry powdery materials, including metal magnesium powder, iron powder, active carbon, aluminium powder, aluminum bauxite, caustic soda(sodium hydroxide), graphite powder, clay, kryocide, chemical fertilizer, plastic, limestone, pigment, carbamide, siliconmanganese alloy, aluminium dross, aluminium skimmings, magnesium chips, dolomite, calcium carbide powder, mud, oxide skin, refined iron ore, copper fine powder, slagging constituent, various kinds of powdery materials, wastage, non-ferrous metal powders, etc. These dry materials are pressed into briquettes for smelting or direct use in smelting field, coal productoin, construction field, chemical field, electricity field, refractory field and so on. It is specially used in metallurgy field, lime briquetting production. It adopts screw pre-press and strong rolling press type. The main shaft is forged by 40 rc, the roller leather adopts antifriction alloy, hydraulic device matched, it is sturdy and durable roller briquetting press machine.

.jpg)

Ce Approved High Efficiency High Pressure Briquette Machine/Stable Performance High Pressure Coal Briquette Machine has installed with self-protection device. The hydraulic pressure protecting device adopts its pump to press the high pressure oil into the cylinder and makes the piston moves with axial displacement. The front connecting end of the piston rod supports the shaft block to meet production requirement. When too many materials or metal blocks enter the space between the two compression rollers, the piston rod of the hydraulic cylinder gets so pressed that the pump will stop working and the energy accumulator will make buffer action facing pressure changing. Then the flood valve starts the oil return and the piston rod replacement will widen the space between the rollers thus forcing hard materials to pass the rollers. Finally, the whole system pressure returns to normal condition so that the rollers won’t be damaged. The dry powder ball pressing machine can be made flexibly by adjusting its pressure according to different ball pressing density.

Henan Fote Heavy Machinery Co., Ltd. has been the professional briquette machine and briquetting plant manufacturer and supplier in China. Technology and innovation are our eternal pursuit. 'High quality, competitive price, the best services and timely delivery' is our philosophy. We hope to fully cooperate with overseas partners on the basis of equality and mutual benefits. We sincerely hope to become your Chinese supplier and partner in the mechanical field. Welcome to visit our factory! We will provide best equipment with high quality and we are satisfied to achieve the target and to meet your requirements.

Contact Information

Email: info@sinoftm.com

Website: http://www.ballpress-machine.com/p_12.html

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

- Country: China (Mainland)

- Market: Africa, Asia, Middle East, Europe, Americas

- Founded Year: 1982

- Address: Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, Henan, China.

- Contact: Oliver Wange