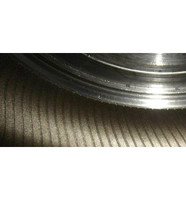

Engineering Tyre Mould

Specifications

|

The mould adopts the segmented mould structure of circular conical surface. The opening stroke is X150mm,Y525mm. The orientation angle of the mould is 15. The upper side wall plate adopts docking pattern structure. There are dowel pins on circumference to prevent dislocation. The lower side wall plate adopts wholly removing tyre, not docking pattern structure. The characters of the mould cavity are carved by CNC. They are neat, orderly and beautiful. The vent hole is installed stainless steel sheath. The mould adopts ZG270-500. The mould surface of bead ring is treated by nitriding. The hardness of the copper alloy The outside surface of the mould is painted high temperature resistance aluminium paint. The surface of the mould cavity is treated by sand blasting. http://www.china-tyre-mould.com |

- Country: China (Mainland)

- Founded Year: 2005

- Address: Xifu Industrial Zone, Chengyang District, Qingdao, China

- Contact: wang li