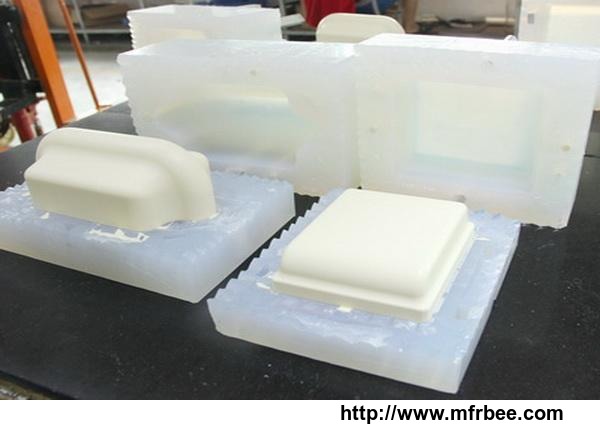

Plastic Vacuum Casting

Specifications

|

Vacuum casting equipment: 3 sets Silicone mold vacuum casting Maximum size is 1000mm×800mm×800mm The tolerance can be controlled to 100mm/±0.20mm Preferred model Formats: x-t, .stp, .igs, .stl, Auto CAD, Pro/E, Unigraphics Lead time: 5~15 days, according to the actual prototyping requirement Silicone mold life: 10 time , but 3~8 times is more better . Thickness of duplication part :≦2.5mm . Vacuum casting cycle time: 50min ~90 min Materials available: ABS, PP, PC, PP, Rubber, Transparent part http://www.youdeprototypechina.com |

- Country: China (Mainland)

- Founded Year: 2005

- Address: Room 301-7A,3/F HongKong Trade Center 161-167 Des Voeux road, Central,HK

- Contact: wang li