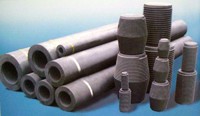

UHP graphite eletrode

Product Quick Detail

- Place Of Origin

- China (Mainland)

- Length

- 1000~2700mm

- Resistance

- 15 max

- Apparent Density

- 1.52 min

- Thermal Expansion

- 2.9 max

- Packaging

- in wooden case

- Delivery

- 25 Days

Specifications

Physical and Chemical properties

| Item | Regular power |

High

power |

Ultra high power | ||||

| Unit | φ150-200mm | φ225-350mm | φ400-500mm | ||||

| Specific electrical resistance (max) | Electrode Nipple | μΩ.m |

9.0

7.5 |

9.0

7.5 |

9.0

7.5 |

7.0

5.5 |

6.0

5.0 |

|

Bending

strength (min) |

Electrode Nipple | MPa |

9.8

13.0 |

7.8

13.0 |

6.4

13.0 |

10.5

14.0 |

10.5

16.0 |

| Elastic Modulus(max) | Electrode Nipple | GPa |

9.3

13.7 |

9.3

13.7 |

9.3

13.7 |

12.0

14.0 |

10.5

15.0 |

| Bulk density(min) | Electrode Nipple | g/m |

1.52

1.63 |

1.52

1.63 |

1.52

1.63 |

1.60

1.70 |

1.65

1.72 |

| Coefficient of thermal expansion(max) | Electrode Nipple | 10-6/℃ |

2.9

2.7 |

2.9

2.8 |

2.9

2.8 |

2.4

2.2 |

1.5

1.4 |

| Ash (max) | % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

- Country: China (Mainland)

- Founded Year: 2012

- Address: north of guochang road at cheng'an county

- Contact: Jerry Shi