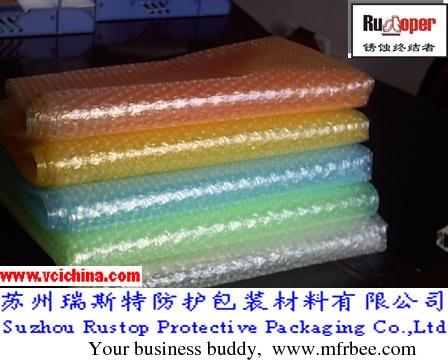

anti corrosion bubble wrap

Specifications

How Rustoper® VCI Works:

a).Forms a molecular layer of protection on meatal surface.

b).Insulates metal surfaces from corrosion-causing contaminants.

c).Creates protective environment in enclosed areas.

We are VCI products manufacturer that specialized in producing and exporting VCI antirust packaging materials and chemicals.

General:

Rustoper (corrosion terminator)VCI cushion materials is a kind of new-type antirust product developed by our company recently,which not only has the cushion function performed by general PE high foaming materials but also provide with antirust protection for a lot of metal products.It is extensively used for the antirust ,anticollision,anti-shock and anti-wear packaging of electronic elements,precision apparatus,instruments and measuring tools and metal products with edges and sharp corners.

Features/Advantages:

1 High-performance VCI is uniformly contained in the interior of the cushion materials and will begin to gasify and play the antirust effects after being packed in the

material.

2 Even if the material does not contact the metal directly, it can effectively perform the function of antirust, so it is especially applicable to metal products with complex

appearance.

3 The material has functions of both antirust and packaging.

4 The material is clean, harmless and non-toxic, so it is safe to environment.It passes SGS certification and meets RoHS directives.

Applicable Metals:

It is applicable to ferrous metal, alloy steel, cast iron, copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy,

nickel and its alloy, tin and its alloy, aluminum and its alloy, and other metal materials and their products.

Application Method:

1 Before packed, the surfaces of the articles for antirust shall remain clean and dry without impurities.

2 The material, when cut into sliver, piece and soon, may be used as the inner packaging cushion material, filler, bedding cushion, etc. for electronic elements, precision apparatus, instruments and measuring tools, precision parts and so on.

3 The material, after compounded of an outer layer such as PE, may also be used directly as a kind of external packaging material, which is applied to the packaging and antirust for machine tools, complete equipment, big hub spindles, etc.

Category:

| Name of Commodity | Type | Model | Specification | Thickness/mm | Color |

| VCI Cushion Materials | Generally applicable to multi-metals | Air bubble film | Width≤1000m | 0.08-0.15 | As required |

| EPE pearl cotton | Width≤1000m | 1.50-2.50 | As required |

Validity Period of Antirust:

One~three years (use according to required specifications)

Custody and Storage:

With sealed package, it shall be kept in a cool, dry place, away from sunshine and no contact with sources of ignition and corrosive materials. The quality guarantee period shall be twelve months from the date of delivery.

Welcome your specific inquiry of our VCI cushion materials!

We are at your service and your requirements will receive our best and prompt attention.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Americas,European Union,Middle East,Oceania

- Founded Year: 2006

- Address: 中国江苏省苏州市甪直镇东方大道甪直科技产业园508室

- Contact: Daisy Chan