stainless steel plates online where to buy metal rods

Specifications

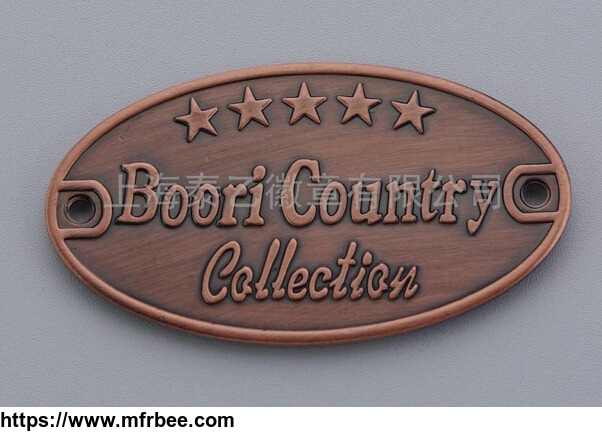

custom metal plates, , custom metal tags. Name Plate

Manufacturers,Custom Name plates,Metal Tags,Metal Labels,Signs, Decals in China.

China Name Plate Manufacturers,we custom name plates,brass plate engraving.

Epoxy signs manual

Epoxy plate manual operation is different from Epoxy plate machining (For more see "Epoxy signage Operating Procedures"), to distinguish between specific request from for

comparison.

1, the first ready for all kinds of substrates, such as: nameplates, badges, medals, etc. into the oven preheating temperature requirement of 60 degrees, the purpose of the

removal of surface moisture.

2, the substrate was placed flat dehumidified consistent level of console board waiting drip.

3. The amount, take a clean beaker, accurate measurement, the B component, a 2: 1 weight ratio of mixing evenly (must be mixed, otherwise there will be sticky and with the

substrate surface

Delamination phenomenon, the manufacturers of the products are the same to do this. ) (Note: the proportion of the manufacturers are not the same, as the case may be).

4, and then with a good mixture into a vacuum oven, open real pump, removing bubbles mix in a vacuum.

5, take in the clean needle, the needle after defoaming Shuijingjiao suction tube, then measure and drip evenly in the prepared substrate (ie: signs, trademarks, etc.) of the

surface, the general Shuijingjiao

Thickness 2mm, let the natural leveling can be (Note: The above process is controlled within 30 minutes, so as not to increase the liquid viscosity, resulting in

inoperable).

6, the substrate 3-5 minutes after instillation Shuijingjiao observe glue surface without bubbles or dust particles, if any small bubbles, usable pin to pierce, found dead have

not stream Shuijingjiao to place, with pin lead

Material:Metal,Aluminum,Anodized Aluminum,Brass,Stainless Steel,Polycarbonate,Polyester,Vinyl.

Website: www.nameplatesmanufacturers.com metal plate manufacturers

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe

- Founded Year: 1994

- Contact: Hansen kem