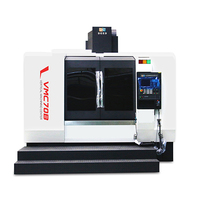

FMC-850L CNC Vertical Machining Center

Product Details

High-precision ball screw machine adopts a C3?40mm abrasive class ball screw of high-precision. There are bevel ball bearings (3 for one group) and pre-draw double-nut caps on both sides of ball screw to reduce accumulated heat error.

High-precision ball screw

The umbrella tool capacity is for 20 knives, and can be used to produce mold and general parts.

Umbrella tool change system

Special cam drive 24-tool knife-arm automatic tool changer, the tool change time is just 2.2 seconds, the tool weight up to 7 kg, tool change smooth,and easy in maintenance. Knife-arm type mechanism is used to change handy tools bidirectional, which can save non-cutting time, and improve working efficiency.

Knife-arm type tool (optional)

Through a special high-speed arc circular tooth-belt-8YU with the connection of belt pulley,the spindle motor completes the main drive system to reduce the skidding phenomenon of belts. The motor speed is much more stable than transmission. In order to ensure maximum axial rigidity, radial rigidity and machining precision, spindle adopts high-precision NSK P4 class bevel ball bearings to get the maximized span configuration according to the calculation and analyses.

Spindle

The main structure of cast iron: Spindle of high rigidity is suitable for heavy cutting. After all aging treatment, high rigid MEEHANLTE cast iron strengthens the internal ribs, so high stability can be achieved and transfiguration seldom happens.

Machine features: With strong bearing ability, wide guided design, and wide processing areas, the machine can effectively improve the mold processing scope, and its strong cutting is extremely good. Besides, it has the feature of high accuracy, rigidity, low noise, strong power, big torque, high speed, high precision, and strong cutting ability. Positioning accuracy and repeat positioning accuracy are tested by the laser interferometer. The machine of good performance can automatically mill planes, tanks, slants, and it's easy to operate and maintenance.

Overall structure

FMC-850L Machine Specifications

|

CNC Vertical Machining Center/VMC: |

CNC Vertical machining center/VMC

1.Strong bearing ability

2.Excellent strong cuttingg effect

3.Rotary worktable

- Controller:Fanuc or Mitsubishi

- Color:as request

- OEM:Available

- Workpiece and Weight:Large Machine Tool

- Automatic Grade:Automatic

- Processing Types:Metal

- Precision:High Precision

- Controlling Mode:Machining Center

- Usage:General

- Processing:milling,boring,turning,etc.

- Model Number:FMC-850L

- Brand Name:FUDA

- Place of Origin:Guangdong China (Mainland)

- Country:China (Mainland)

- telephone:86-757-85606626

| Delivery Time: | 45 days after deposit |

| Package: | Standard exporting package or as request |

| Supply Ability: | 10 Set/Sets per Quarter |

| Minimum Order Quantity: | 1 Set/Sets |

| Payment Terms: | T/T |

| Port: | Shenzhen,China |

| Processing Types: | Metal |

| Precision: | High Precision |

| Controlling Mode: | Machining Center |

| Usage: | General |

| Processing: | milling,boring,turning,etc. |

| Model Number: | FMC-850L |

| Brand Name: | FUDA |

| Place of Origin: | Guangdong China (Mainland) |

Send inquiry / quota request to FMC-850L CNC Vertical Machining Center

Relate products of FMC-850L CNC Vertical Machining Center

As a vmc machine company, DEED VMC-series Vertical Machining Center is mainly suitable for processing complex parts such as plates, discs, molds, and small shells. The vmc milling machine can complete the processes of milling, boring, drilling, tapping, and thread ...

VL series vertical machining center is a small and medium-sized vertical machining center designed by Germany and made in China. It mainly aims at the milling of automobile aluminum hubs, completing drilling, complex surface machining, and other processes; This product can also ...

China vertical machining center Our vmc machine types mainly include VMC and VL two series, VMC series include VMC50B VMC milling machine, VMC50C VMC milling machine, VMC60B VMC milling machine, VMC60C VMC milling machine, VMC70B VMC milling machine, VMC70C VMC milling machine. ...