Extrusion Processing is a process whereby moistened, expansile, starchy or proteinaceous components are plasticised within an extruder barrel by a combination of pressure, heat and mechanical

shear. This causes increased product temperature, gelatinisation of starches, de-naturation of proteins, changes to the structure of tractile components, shaping of the end product and exothermic

expansion of the extrudate which can be further processed to become part or finished product. A wide range of products can be produced from cereal flours, starches, defatted proteins and mixtures

of these and other components, thus providing virtually open ended product design and development opportunities. OVO? FINE POWDER EXTRUDERSOVO?Mixer Extruder Systems for Fine Food & Pharmaceutical

Powders for thorough agglomeration of components, de-activation of enzymes extruded as fine particles, granules or special shapes to suit further processing. These applications of OVO?Extrusion

Technology are State-of-the-Art and are currently subject to Patent Application. We can only provide a working description of our equipment in operation if we have detailed information about the

components which are to be processed. Cereal & Legume Cooker Extrusion Technology does not usually apply to sensitive Dairy Bi-Products for which we would need to be provided with detailed

specifications and possibly samples for evaluation at our R&D Centre. We would need to have all parties concerned sign our Standard Confidential Disclosure Agreement and by the same token we

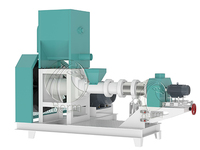

would sign similar documents from the Client Company. OVO? FOOD EXTRUDERSABALINK?Technology have a background of over thirty (30) years designing and building Cereal and Pulse Cooker Extruders

including complete Processing and Packaging Plants from Grain Storage, Mixing and Conditioning to OVO?Extruders from which freshly formed collets are conveyed into the UVIRTOS?Infra-Red, Stainless

Steel Trommel Oven then gravitating down a Chute into the Stainless Steel Flavour & Nutrient Mixing Trommel mounted underneath the Trommel Oven from which the finished baked and flavoured product

is conveyed to the ABAPAK?Form Fill & Seal Machines which pack the health snackfoods into gas flushed, date coded packages, ready for loading into cartons for distribution. The smallest version of

this complete Automatic Plant is known as the SNACKMASTER?360K. OVO?Single Screw Cook & Cool Extruders are also available for a wide range of applications based on a primary feed of Food or

Chemical Doughs which do not require High Degrees of Expansion but rather a reliable way to automatically produce a range of Cooked, Cooled, Extruded and Cut Product. OVO?Cereal Extruders are

available in a range of sizes, configurations and production rates with Single Screw, Twin Screw Co-Rotating, and State-of-the-Art Twin Screw Counter Rotating Models from small 60 Kg per hour

Variable Geometry Research Machines to 150 Kg, 300 Kg, 600 Kg and 900 Kg per hour production rates up to 9000 Kg per Hour Aquafeed Extruders. OVO?Screw and Die Configurations can be matched to suit

a whole new range of products from Japanese Crumbs, Special Crumble Coatings through all shapes and sizes of snackfoods, breakfast cereals, plain and filled crispbreads etc. A superb range of Pet

Foods, Aquaculture Feeds, Stockfeed, controlled release garden products and bio-degradable packing products can also be produced on our OVO?Extrusion, Processing and Packaging Plants which are all

automatic and continuous in operation and can be shipped by container anywhere in the World, complete with Power Generator if required, in Developing Countries and or emergency situations when

Micro-Nutrients can be included in the Flavouring System for specialised dietary requirements. OVO?TWIN SCREW COUNTER ROTATING EXTRUDERSThe OVO?COURO?Range of Counter Rotating, Precision Mesh, Twin

Screw Extruders are now available in a wider range of Product Categories and capacities to suit most standard applications. ABALINK?have a background of over thirty years designing and building

Cereal & Pulse Cooker Extruders including complete Processing & packaging Plants from grain storage, mixing and conditioning to OVO?Extruders from which freshly formed products are conveyed to the

UVIRTOS?Infra-Red 316 Stainless Steel Trommel Oven, then gravitating down a SS Chute into the SS Flavour and Nutrient Mixing Trommel mounted under or in-line with the Oven from which the finished,

flavoured product is conveyed to the ABAPAK?Form, Fill & Seal Automatic Packaging Machines which can pack the product into Gas Flushed, Date Coded Simplex or Duplex Packages, ready for loading into

cartons from the Rotary Packoff Tables which collect the packs off each ABAPAK? OVO?Cereal Extruders are available in a range of sizes and configurations from Single Screw, Twin Screw Co-Rotating

CORO?Models, to State-of-the-Art Twin Screw Counter-Rotating COURO?Models, from small 60 Kg per hour Variable Geometry Research Machines through a range of Four basic Models, up to the 9000 Kilo

per hour Aquatic Feed Machine. The following chart indicates the Model and Production Rates for each Product Category made on our COURO?Range.

These applications of OVO?Extrusion Technology are State-of-the-Art and are currently subject to Patent Application.