Sell microcomputer control system @China (Mainland)

Microcomputer controller - automatic & convenient

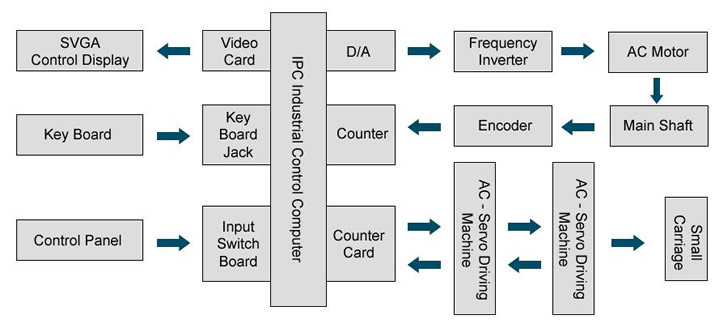

Microcomputer control system, as its name implies, is the control part of whole DFW production line and its performance impacts the quality of FRP pipes directly. This system features forth-generated winding program co-developed with Tsinghua University. Meanwhile, advanced LINUX control system is applied to break the limitation of traditional DOS system.

Microcomputer control system

Highlight:

-

High quality composition

- Adopting quality Advantech IPC as our host computer for excellent environmental adaptability.

- The carriage driving system is composed of Japanese Yaskawa AC servo drivers and motors which use pulse single inputting methods for minimizing disturbance.

- Applying Fuji frequency transformer to adjust the speed of principal shaft.

-

Full automation

The whole winding process is carried out fully automatically - no need of any transferring action. -

High precision

Microcomputer control system allows for high precision without any zero drift phenomenon. Meanwhile, its accuracy can reach ± 0.02mm to ± 0.2mm. -

Strict movement control

Adopting PID positional servo control system, our microcomputer controller ensures the movement of mandrel and guiding head accurately under any circumstances. -

Easy operation

This system adopts humanized working interface in simple design. Only a few parameters should be input to reduce the human error to the largest extent; meanwhile, the products and parameters can be quickly input according to process list. Most of all, our microcomputer control system helps to correct the wrong parameters automatically. -

Convenient adjustment

Microcomputer control system can store numerous parameters for convenient reference and usage. Meanwhile, its operation panels allow for free switch among automation, semi-automaton and hand operation to meet different customers’ needs.

Control table of microcomputer control system

Post by Joy Li Manufacturing & Processing Machinery @2015-01-29 04:01:28

Contact with Joy Li