Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics plastic injection mold has been widely applied to various industries. As a result, electronics injection mold manufacturers have been ta

Glitter Mold Technology Co., Ltd [2022-09-16 09:07:25 ]

2k injection molding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of th

Glitter Mold Technology Co., Ltd [2022-09-16 09:04:49 ]

Two Shot Tool Construction Part two shot tool construction saves the injection machine quantity and plant area, lower the labor cost and minimize the part handling, although mould cost is high but later process cost is lower, not on... Two Shot Plastic Injection Molding Parts How

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:40:40 ]

Soft Prototype Mold Prototype mold is a kind of test mould before mass production mould, customer make test mould for design verification, Product structure, part function analysis or produce small lot parts for other... As a tool supplier whose goal is becoming an expert in the

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:38:30 ]

Injection Plastic Mold Injection plastic mold is another name for plastic injection mold. This is just how people in various places call injection molds differently. The injection plastic mold can be made as single cavity plastic mold or multi cavities injection mold according to

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:37:31 ]

The runner filling balance must be considered when designing the multi cavity plastic mold in order to ensure the best effect of filling balance, the multi cavity mold will be multiple of 4 to design the mold generally, such as 4. 8. 16. 32. 64. 128 points, etc. ; Most of the mul

Unique Solutions Mold [2022-08-15 14:49:00 ]

Multi Cavity Medical Mold USM is an ISO9001 2015 certified plastic moulding services factory, with over 15 years of professional experience and advanced equipment, we\'ve got many successful cases in multi cavity soft plastic mold, there are 10 engineers could assist our customer

Unique Solutions Mold [2022-08-15 14:47:54 ]

Taizhou Huangyan Rongdu Mould Co., Ltd. is a company with more than 30 years of experience in the professional development and manufacturing of all kinds of plastic mold. The company specializes in producing plastic tray molds, turnover box molds, trash cans molds and daily neces

Taizhou Huangyan Rongdu Mould Co., Ltd. [2022-08-11 15:13:09 ]

Mould Spare Parts Plastic mold accessories include single section shoot, double section shoot, double section shoot, flat tip, flat tip, positioning column, plastic mold guide sleeve, straight sleeve, middle column sleeve, plastic mold guide sleeve, etc. Features of Mould Spare P

Glitter Mold Technology Co., Ltd [2022-07-18 11:30:10 ]

Mould Slide The mould slider is a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction during the opening and closing action of the mold. Features of Mould Slide When the product structure makes it impossible for the mold to

Glitter Mold Technology Co., Ltd [2022-07-18 11:29:34 ]

Mould Component Mould Components are also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing

Glitter Mold Technology Co., Ltd [2022-07-18 11:28:50 ]

Mould Base After years of development, mold base production industry has been quite mature. Large plastic injection molding companies can purchase customized mold base according to individual mold needs, and also choose standardized mold base products. Features of Mould Base The

Glitter Mold Technology Co., Ltd [2022-07-18 11:28:04 ]

As a kind of mold steel used for plastic production, plastic mold steel is main material of plastic mold. The plastic mould steel has enhanced the development of industrial products to be advanced, diversified, individualized, and high value-added. All countries in the world coun

Jiangsu Hongsheng Heavy Industry Group Co., Ltd [2022-07-15 15:22:24 ]

As modified high-toughness, high-isotropy, high-quality hot work & plastic mold steel, the steel has good cold and hot fatigue resistance and corrosion resistance, good cold and hot workability, good hardenability, and high thermal strength and oxidation resistance performance at

Jiangsu Hongsheng Heavy Industry Group Co., Ltd [2022-07-15 15:20:42 ]

Our houseware mould can produce everything needed for daily life. From bathroom to kitchen, from storage to cleaning supplier, Jeward Mould offers various types and styles of plastic houseware products. Advantages of Jeward Houseware Moulds It\'s hard to find a house without plas

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-05-23 10:20:29 ]

From indoor to outdoor, from adult to kid products, you can find all kinds of injection moulds for plastic chairs and sofas in Jeward Mould, a plastic chair mould manufacturer in China. The injection moulded chairs produced by Huangyan Mold include light and economic classical ch

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-05-23 10:19:37 ]

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mou

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-05-23 10:19:17 ]

Insert molding is a molding method to make integrated products. Ⅰ. Definition of insert molding Plastic insert molding means that after inserting a pre-prepared dissimilar material into the mold, injecting resin and molten material, and finally joining with the insert to solidi

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-05-23 10:18:57 ]

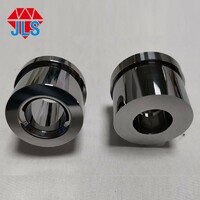

Rectangular Ejector Pin Ejector Pins And Punches Ceramic Ejector Pin Molding Ejector Pin Wc Precision Punch Carbide Ring Gages Special Wear Parts Die Components Headed Type Punches Stepped Relief Die Buttons Stepped Die Buttons Precision Plastic Mold Parts Latch Lock Pre-Centerin

Dongguan JLS Precision Mold Parts Co.,Ltd. [2022-05-17 14:32:11 ]

Shoulder Guide Pins Iso Punches Puller Pins And Bushings Shuttle Mold Locks Taper Locks Piercing Punches Punching Dies Friction Components Mold Parts Ejector Pins Plastic Mold Parts Injection Mold Parts Ejector Pin Shoulder Pin Ejector Sleeve Mold Components Tungsten Carbide Punc

Dongguan JLS Precision Mold Parts Co.,Ltd. [2022-05-17 14:27:57 ]